Did you know that label printing errors cost manufacturers and distributors millions each year? In the fast-paced world of logistics, inaccuracies in shipping labels can lead to delayed deliveries, increased operational costs, and unhappy customers. Scaling your shipping label printing process is not just about meeting the demands of a growing business; it’s about efficiency, accuracy, and customer satisfaction. In this comprehensive guide, we’ll explore the challenges of shipping label printing, the impact of errors on businesses, and practical strategies to scale your operations seamlessly.

The Costly Consequences of Label Printing Errors

According to industry reports, label printing errors account for a substantial portion of financial losses in the manufacturing and distribution sectors. Inaccurate labels can result in shipment delays, misrouted packages, and increased labor costs associated with rework. In fact, studies show that shipping errors contribute to a significant percentage of returns, leading to additional expenses for reverse logistics and potential damage to a company’s reputation.

One of the primary contributors to label printing errors is the manual nature of traditional printing processes. As businesses grow, relying on manual data entry and printing methods becomes increasingly unsustainable. This is where scaling your shipping label printing process becomes not just an option but a strategic imperative.

Scaling Strategies for Shipping Label Printing

Reviewing scaling strategies for shipping label printing is essential for businesses looking to optimize their logistics operations and adapt to growing demands. As e-commerce continues to surge and customer expectations for fast and accurate deliveries rise, organizations must ensure that their shipping label printing processes can scale efficiently to meet increased order volumes.

By evaluating scaling strategies, businesses can identify bottlenecks, streamline workflows, and implement technology solutions such as automation and cloud-based printing platforms. This proactive approach not only improves operational efficiency and reduces shipping errors but also enhances customer satisfaction and strengthens the organization’s competitive edge in the marketplace.

- Invest in Automated Label Printing Systems: Transitioning from manual label printing to automated systems is a crucial step in scaling your operations. Automated label printing solutions integrate with your existing order management or warehouse management system (WMS), reducing the risk of human errors associated with manual data entry. These systems can generate labels in real-time, ensuring accuracy and consistency across all shipments.

- Implement Barcode Technology: Barcode labels play a pivotal role in streamlining shipping processes. By implementing barcode technology, you not only improve the speed and accuracy of label scanning but also enable better tracking and traceability throughout the supply chain. Barcodes reduce the likelihood of errors associated with manual data input, making them an essential component of a scalable shipping label printing strategy.

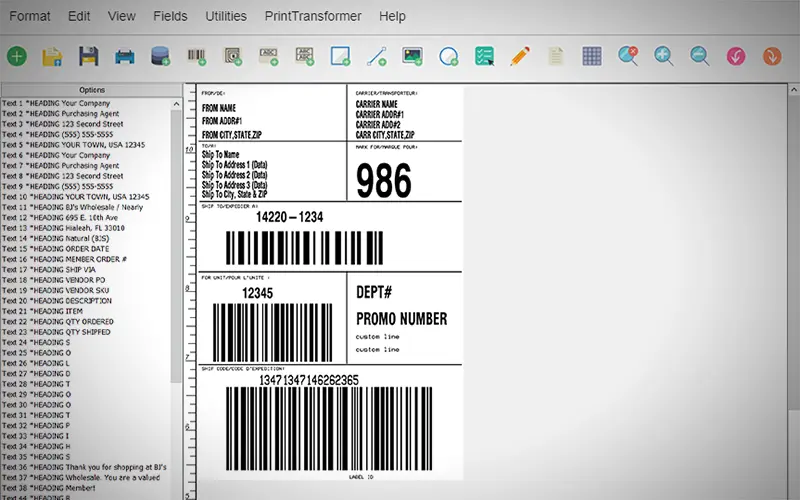

- Centralized Label Management System: A centralized label management system is instrumental in maintaining control and consistency in label printing. This system allows you to create, manage, and update label templates from a centralized platform. Whether you have multiple distribution centers or operate in different regions, a centralized system ensures that labels adhere to predefined standards, minimizing errors and promoting uniformity in branding.

- Integration with Enterprise Resource Planning (ERP) Systems: Integrating your shipping label printing process with your ERP system enhances overall operational efficiency. ERP integration ensures seamless communication between different business functions, streamlining the flow of information from order processing to label generation. This integration minimizes the risk of data discrepancies and ensures that the most up-to-date information is reflected in each label.

- Scalable Label Design Software: As your business expands, so do your label design requirements. Invest in label design software that can scale with your evolving needs. Look for solutions that offer a user-friendly interface, support for various label formats, and the ability to incorporate dynamic data fields. This ensures that you can easily adapt your label designs to changing regulations, customer requirements, and branding standards.

- Cloud-Based Solutions for Accessibility: Embrace cloud-based label printing solutions for enhanced accessibility and flexibility. Cloud-based systems allow authorized personnel to access label printing functionalities from anywhere with an internet connection. This is particularly beneficial for businesses with multiple locations or remote teams, ensuring that label printing is a centralized yet accessible process.

Benefits of Scaling Shipping Label Printing

- Increased Accuracy: Automated systems and barcode technology significantly reduce the chances of human errors in label printing. By eliminating manual data entry and leveraging technology, businesses can enhance the accuracy of shipping labels, minimizing the risk of misrouted shipments and related errors.

- Faster Turnaround Times: Scalable label printing systems, integrated with other operational processes, contribute to faster turnaround times. Real-time label generation and printing ensure that shipments can be processed swiftly, meeting customer expectations for timely deliveries.

- Cost Savings: While the initial investment in scalable label printing solutions may seem substantial, the long-term cost savings are considerable. Reduced errors lead to fewer returns and associated costs, and streamlined processes result in operational efficiencies that contribute to overall cost savings.

- Improved Customer Satisfaction: Accurate and timely deliveries are fundamental to customer satisfaction. Scaling your shipping label printing process ensures that customers receive the correct items on time, fostering positive experiences and building trust in your brand.

- Adaptability to Business Growth: As your business expands, the ability to scale your shipping label printing operations becomes crucial. Scalable solutions grow with your business, accommodating increased order volumes, new product lines, and changing industry regulations.

Conclusion

In the competitive landscape of modern logistics, the importance of scaling shipping label printing processes cannot be overstated. The cost of errors, both financial and reputational, underscores the necessity for businesses to adopt scalable and automated solutions. Investing in advanced technologies such as automated label printing systems, barcode technology, centralized label management, and cloud-based accessibility positions businesses for sustained growth, improved operational efficiency, and heightened customer satisfaction.

The 8 Elements of a Robust Label Management System

As the demands on the supply chain continue to evolve, scaling your shipping label printing becomes not just a strategic choice but a critical component of a resilient and customer-centric logistics strategy.