INTELLIGENT RFID TRACKING, LABELING & FORM SOLUTIONS FOR THE CANNABIS INDUSTRY

Track Every Plant. Label Every Product. Stay Compliant.

From seed to sale, accuracy and compliance are everything. CYBRA’s RFID tracking and barcode labeling solutions help cannabis growers, processors, and retailers manage inventory, prevent loss, and meet strict regulations—seamlessly and efficiently.

High-Precision Tracking for a Growing Industry

Keep your operation rolling with RFID and barcode solutions that track every plant, product, and package—ensuring compliance, reducing waste, and keeping your supply chain in perfect harmony.

See-to-Sale RFID Tracking

Monitor every plant from cultivation to distribution with real-time RFID tracking, ensuring compliance and full traceability.

Automated Compliance Labeling

Easily print METRC-compliant labels, potency information, and regulatory warnings without delays or errors.

Loss Prevention

Prevent shrinkage and unauthorized movement of high-value products with automated tracking and real-time visibility.

Production Tracking

Keep production on schedule by tracking flower, extracts, and edibles as they move through each stage of processing.

Smart Shipping Validation

Verify every shipment before it leaves your facility, reducing misdeliveries, chargebacks, and compliance issues.

Greenhouse & Facility Monitoring

Ensure plants are in the right place at the right time while monitoring environmental conditions with RFID-integrated tracking.

Fast, Flexible Label Printing

Print barcode, RFID, and compliance labels on demand—customized for product batches, strains, and state regulations.

Retail & Dispensary Integration

Sync inventory seamlessly with dispensaries to ensure real-time stock updates, faster transactions, and fewer supply chain disruptions.

CANNABIS PRODUCTION CHALLENGES

Miscounted inventory. Untracked plants. Compliance headaches.

Every missing product, mislabeled package, and outdated manual process puts your business at risk. In cannabis production, accuracy isn’t an optional luxury—it’s the law.

CANNABIS TRACKING

- MMisplaced Plants & Equipment

- MDisorganized Inventory

- MSlow Harvested Flower Processing

- MLost Cannabis Products

- MLack of Visibility in Prodcution

COMPLIANCE LABELING

- MInaccurate Labeling

- MConfusing Compliance Requirements

- MManual Label Updates Slowing Production

- MPrinter Compatibility Issues

- MManaging Strain, Potency, and Expiration Labels

OUR PRODUCTS

Stay on Track & In Compliance—No Haze, No Headaches.

From seed to sale, every plant, product, and package needs to be accounted for. CYBRA’s RFID tracking and labeling solutions help cannabis producers grow their efficiency, keep inventory in check, and roll out compliance-ready labels with ease.

EdgeMicro

RFID Starter Software

Ready to test RFID without a high upfront cost? EdgeMicro is a simple, budget-friendly solution to keep your cannabis inventory in check. Perfect for small grow operations or pilot projects, it helps you track plants and products with ease—before scaling up.

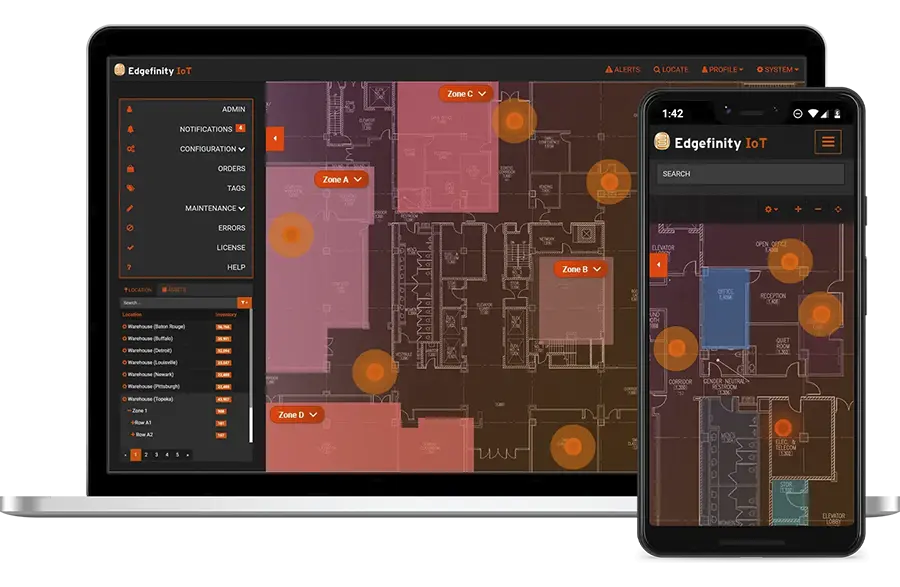

Edgefinity IoT

Enterprise RFID Software

No more lost inventory or compliance blind spots. Edgefinity IoT gives cannabis producers full visibility from cultivation to dispensary. Track plants, packaging, and finished products while reducing shrinkage and costly errors.

MarkMagic

Barcode Label Software

Cannabis labeling doesn’t have to be a buzzkill. MarkMagic makes it easy to design and print compliant labels, strain tags, and packaging barcodes—ensuring accuracy, compliance, and a smooth workflow at every stage of production.

Seamless Integration with

Leading WMS & ERP Platforms.

Sync RFID tracking and labeling with your WMS and ERP systems to keep your plants, products, and compliance efforts perfectly aligned—from seed to sale.

Manhattan

VAI

Acumatica

NetSuite

Flourish

PARTNER WITH THE BEST

Cannabis production compliance moves fast—don’t let outdated systems leave you dazed.

Keep your plants, products, and packaging on track with solutions that simplify labeling, inventory management, and compliance—so you can focus on growing your business.

THE PLAN

Take Control in 3 Steps

1

Assess Your Needs

Tell us about your cannabis production challenges—whether it’s tracking plants, managing inventory, or meeting compliance requirements.

2

Get a Tailored Plan

We’ll recommend solutions that optimize your grow operation, from RFID tracking to automated labeling.

3

Boost Efficiency & Visibility

With our support, implement the right tools to streamline workflows, prevent loss, and ensure every product is accounted for.