Barcode labeling systems are one of the main operational mechanism that keep modern supply chains fast and nimble. But a lot of companies may be carrying out their labeling and barcoding inefficiently. This makes for throttled operations, and can also leave companies open to a number of pitfalls and penalties.

Some examples include:

- Noncompliance of labeling regulations

- Inaccurate barcode readings

- Flaws in packaging.

By implementing this technology, businesses can streamline operations, reduce human error, and gain valuable insights into their supply chain. However, deploying a barcode labeling system requires careful planning and consideration. In this article, we will explore the key components and steps needed to successfully implement a barcode labeling system.

Understanding Barcode Labeling Systems

A barcode labeling system is a combination of hardware and software designed to create, print, and manage barcode labels. These labels, when scanned with a barcode scanner, provide essential information about a product, asset, or location. They are used in a wide range of industries including retail, manufacturing, logistics, healthcare, and more.

5 Big Features Every Modern Labeling System Needs

Labeling systems need to do more than print labels. To support compliance, accuracy, and scale, today’s solutions must include these five essential features ...

Key Components of a Barcode Labeling System

This technology streamlines processes, reduces errors, and provides real-time visibility into your inventory. Here are the key components required to deploy an effective barcode labeling system.

Barcode Labels

The first and most obvious component is the barcode labels themselves. These labels contain encoded information that can be read by a barcode scanner. Labels come in various forms including adhesive stickers, hangtags, and integrated labels (labels embedded within packaging)

It’s important to select labels that are compatible with your specific use case, taking into consideration factors like material, size, and adhesive strength.

Barcode Printers

Barcode printers are specialized devices designed for producing high-quality, durable barcode labels. They come in different types, including thermal transfer and direct thermal printers. Thermal transfer printers use a ribbon to transfer ink onto the label, making them more durable and suitable for applications where labels may be exposed to harsh conditions.

Direct thermal printers, on the other hand, create labels by applying heat directly to the label paper and are often used for short-term applications.

Barcode Scanners or Readers

A barcode scanner is a crucial tool for reading the encoded information on the barcode label. There are various types of barcode scanners, including handheld scanners, stationary scanners, and mobile computer-based scanners.

The choice of scanner will depend on the specific needs of your business, such as the volume of scanning required and the environment in which it will be used.

Label Design Software

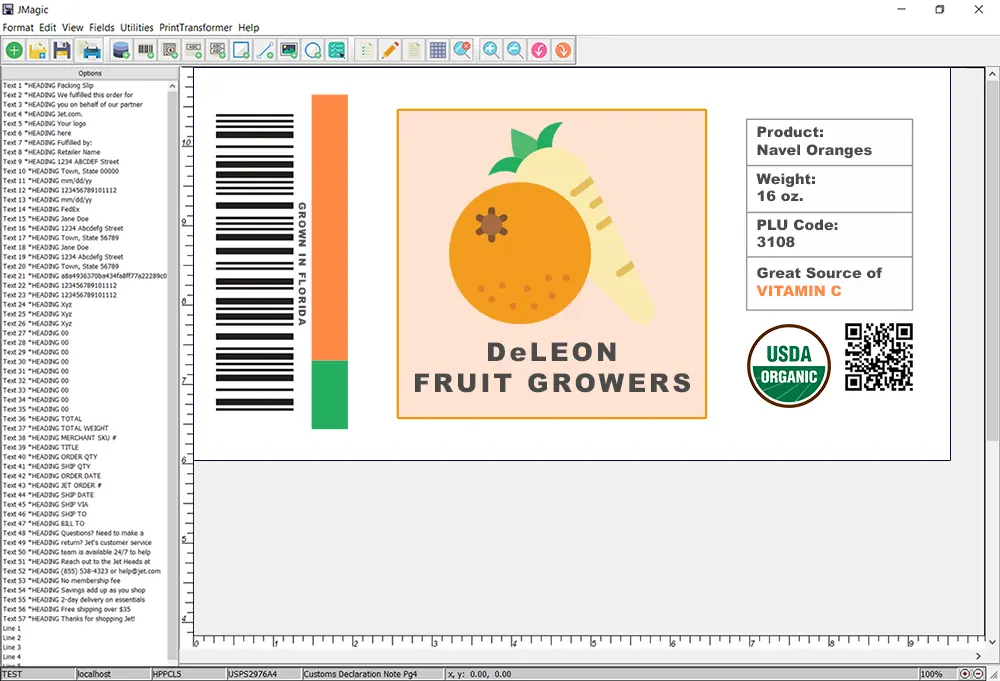

Label design software allows you to create and format barcode labels at scale. It provides a user-friendly interface for designing labels, adding text and graphics, and encoding data into barcodes. Additionally, it should support various barcode symbologies (e.g., UPC, Code 128, QR codes) to ensure compatibility with your existing systems and industry standards.

Database or Inventory Management System

For a barcode labeling system to be effective, it needs to be integrated with a database or inventory management system. This system serves as the central repository for information related to products, assets, or locations. When a barcode is scanned, the scanner communicates with the database to retrieve the relevant information associated with that barcode.

Steps to Deploy a Barcode Labeling System

Deploying a barcode labeling system involves several key steps to ensure its seamless integration into your business operations. Here’s a comprehensive guide on how to go about it:

Assessment and Planning

Begin by conducting a thorough assessment of your business’s needs. Identify what items or processes will be labeled, the type of labels required, and the volume of labels to be printed. This information will help guide your choices in terms of labels, printers, and scanners.

Selecting Hardware and Software

Based on your assessment, choose the appropriate barcode printers, scanners, and label design software. Consider factors such as compatibility, durability, and scalability to ensure that your chosen components will meet your current and future needs.

Integration with Existing Systems

Integrate the barcode labeling system with your existing database or inventory management system. This will allow for seamless communication between the barcode scanner and the central repository of information.

Label Design, Migration, and Testing

Use label design software to create, format, and convert labels from raw ZPL into human-readable, editable layouts. This allows teams to standardize label formats, make updates without rewriting code, and test labels to ensure barcodes scan accurately and pull the correct data from the database.

Monitoring and Maintenance

Regularly monitor the performance of your barcode labeling system. Address any issues promptly and perform routine maintenance on the hardware and software to ensure optimal functionality.

Conclusion

Deploying a barcode labeling system can significantly enhance the efficiency and accuracy of your business operations. By carefully considering the key components and following the steps outlined in this article, you can ensure a successful implementation.

Remember that a well-planned and integrated barcode labeling system can be a powerful tool for improving inventory management and gaining valuable insights into your supply chain.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.