Radio-frequency identification (RFID) tags provide powerful innovations for organizations in all sorts of industries and niches. From retail to pharma, manufacturing, utilities, and beyond, RFID is a technology that can assist teams in maintaining and tracking goods, equipment, assets, or inventory. RFID tags are tiny chips that are used to identify and track objects using electromagnetic fields. Unlike barcodes, they do not require physical contact with a reader, making it possible to read entire pallets or truckloads of goods. This makes RFID technology ideal for applications like smart label tracking. RFID stickers are a simple application that allow tags to be applied to virtually any piece of equipment or inventory.

Typically, RFID tags are designed for rugged, outdoor-based applications that can withstand harsh environmental conditions. These tags are often attached to cargo containers, vehicles and light rail cars for vehicle tracking, cargo identification and supply container tracking.

What are RFID Stickers and Tags?

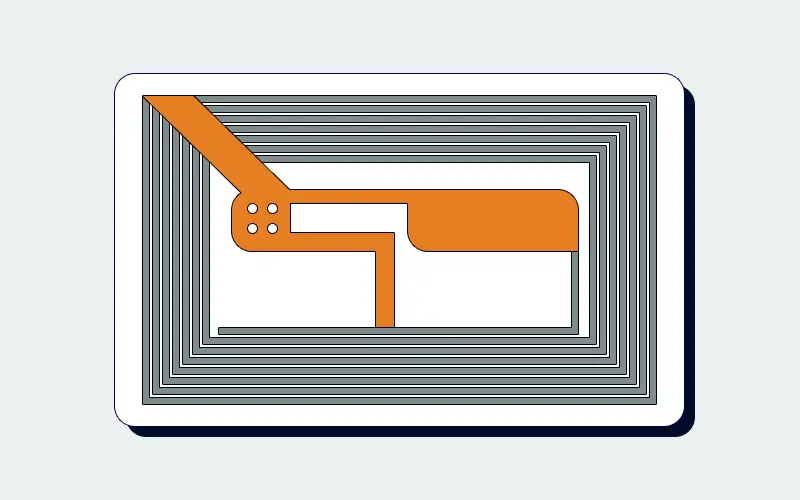

RFID stickers are similar to barcode labels or price tags, but they have a special inlay inside that can be read by an RFID reader. They can be used to track tools, equipment, inventory, assets, people and objects.

They are used in a variety of industries for many different applications, including inventory management and supply chain tracking, access control, asset tracking and animal identification. They can also be used to make contactless payment cards or electronic toll collection.

Free RFID Consultation

Do you need to add RFID to your operations? Let us help! We’ve been working with companies to help them leverage RFID implementations, and identify ways they can benefit from RFID. Key solutions include:

- Tracking and tracing inventory and goods.

- Preventing items from unauthorized usage.

- Ensuring equipment is not taken off premises.

- Check where items are stored for quick finding.

What are the Differences Between a Passive and Active RFID?

A passive RFID tag does not contain a battery and is powered by radio waves. When a passive tag comes into range of an RFID reader that is transmitting a signal, it’s antenna sends out a reply with its unique ID number and is picked up by the reader.

The decision to use either passive or active will ultimately depend on the use case. If your project requires real-time monitoring, you will need active RFID. Some examples for this include personnel safety monitoring, high value inventory control, and tracking inventory that has strict handling requirements. For RFID projects that do not require real-time visibility, passive RFID is likely the right choice. Examples of a passive RFID project include check-in / check-out systems, shipping and receiving validation, or work in process systems.

What are the Advantages of RFID Versus Barcodes?

The main difference between RFID and barcode technology is that a RFID tag is read by radio waves instead of a scanner. Since RFID tags don’t need line of sight, you can scan them from a distance, which saves time and money.

Besides reading, the tags can also communicate with other devices via a radio signal. This allows for more precise and accurate tracking.

Another advantage of RFID over barcodes is that the information stored on them can be changed, and it can be updatable to meet changing needs. The data can also be encrypted, which makes it more difficult to counterfeit and replicate.

Although RFID stickers and tags are more accurate, they can cost more than traditional barcodes and don’t provide multiple data sources on the same object. That’s why they may not ever replace barcodes completely.

RFID Sticker Power Levels

The frequency range of radio waves that can be used by RFID equipment and tags are determined by the standards set by the European Telecommunications Standards Institute (ETSI). These are limited to 865 – 868 MHz. In North America, the Federal Communications Commission (FCC) regulates the use of radio waves and limits equipment and tags to the frequency range of 902 – 928 MHz.

The UHF (ultra-high-frequency) range of 860 MHz-956 MHz is a popular choice for many companies. However, this frequency isn’t globally accepted because it would not be able to cover all of the world’s population. This is why manufacturers need to develop RFID devices that work with multiple frequency bands, such as the EPCglobal Gen-2 and ISO 18000-6C.

Regulatory Standards

The RFID industry has developed a number of technical and compliance standards. The most important of these is the EPCglobal specification. This is a universal standard that can be applied to almost all RFID tags and equipment worldwide.

A typical RFID tag is a silicon-on-insulator chip that has four memory banks. Each of these memory banks stores a different set of data about the object or device being tagged. These memory banks can include the Electronic Product Code (EPC), Toll ID, User ID and Reserved ID.

RFID tags are used in a variety of applications, including tracking and monitoring of products at the point of sale, inventory control and tracking, identifying employees, providing secure access to buildings and premises, and measuring performance of machinery and other industrial assets.

Standardization is an important consideration for a growing number of industries, because it makes it easier to produce and sell the same product to different clients. It also reduces production costs because it allows industry resources to be manufactured on large scale and meet certain specifications.

These standards also help to create a more efficient manufacturing process, which allows for lower costs and faster turnaround times. They can even improve the productivity of employees by allowing them to work more efficiently with industry resources that meet industry-wide standards.

Moreover, standards allow industry resources to be made on large scale, which reduces the need for expensive research and development. This enables companies to save money in the long run because they can buy their devices more affordably and get better return on investment because they can be used more often.

Getting Started with RFID

RFID stickers are simply one part of a larger system that allows organizations to track inventory, equipment, and/or personnel. An RFID tracking application can offer a wide range of solutions for companies in virtually any industry:

- Track and trace WIP (Work in Process) goods

- Prevent items from unauthorized usage

- Monitor safety status of personnel

- Ensure vital equipment is not taken off premises

- Keep track of reusable bins and equipment

- Audit outbound shipments to reduce chargebacks

- Check where items are stored for quick finding

If your organization needs to improve shipping efficiency, inventory control, or equipment management, an RFID system would be a powerful addition to your company’s supply chain.