Real-time visibility isn’t just a buzzword — it’s a measurable performance driver. Traditional inventory methods often deliver accuracy rates near industry averages of 65–75%, leaving businesses blind to stock discrepancies and vulnerable to stockouts or overages. In contrast, RFID systems deployed in retail and supply chains routinely achieve 95%–99% inventory accuracy, giving organizations a much clearer, up-to-the-minute view of where items actually are.

As a result, companies that invest in RFID see dramatic improvements in tracking speed, audit efficiency, and operational confidence. Daily or weekly cycle counts become possible because RFID can read thousands of tags in minutes, instead of hours, and systems update inventory records automatically as items move through doors or zones.

In this article, we’ll explore how RFID’s real-time visibility advantage works, why it outperforms manual and barcode-based tracking, and how it helps organizations reduce blind spots, eliminate delays, and make faster, more confident decisions.

Why RFID Is Ideal for Real-Time Visibility

RFID is uniquely suited for real-time visibility because it captures data automatically and continuously, without requiring line-of-sight scans or manual intervention. As tagged items move through doors, zones, or work areas, RFID systems update locations instantly—eliminating delays, blind spots, and human error that slow traditional tracking methods.

Because RFID can read many items at once and update systems in real time, it provides a live, accurate view of operations as they happen—not hours or days later.

RFID is especially effective for real-time visibility in:

- Warehouses and distribution centers for live inventory and location tracking

- Manufacturing floors to monitor work-in-process (WIP) and material flow

- Retail stores and backrooms for accurate, always-on inventory visibility

- Yard and dock environments to track pallets, containers, and shipments

- Healthcare facilities to locate equipment, supplies, and critical assets

- Asset-intensive operations where items move frequently across large areas

In environments where speed, accuracy, and continuous awareness matter, RFID delivers real-time visibility that manual scans and barcode systems simply can’t match.

#MakeRFIDEasy

The RFID revolution is here. And CYBRA is at the forefront, ready to make the technology easier and more accessible than ever before.

Other Technologies to Consider for Visibility

Several technologies can support visibility and tracking, depending on the use case. Barcodes remain a low-cost option for basic identification, but they rely on manual scans and provide only periodic updates. Near Field Communication (NFC) enables short-range, tap-based interactions and is useful for authentication or check-in scenarios, but it still requires deliberate user action and does not provide continuous visibility.

Bluetooth Low Energy (BLE) and Wi-Fi–based tracking can deliver location awareness, but they require battery-powered devices, additional infrastructure, and ongoing maintenance. GPS works well outdoors, yet it lacks the precision needed inside facilities.

While each of these technologies has its place, none combine automation, accuracy, scalability, and cost-effectiveness the way RFID does—especially in indoor, high-volume environments.

For that reason, we’ll focus on how RFID enables true real-time visibility and why it has become the preferred solution across warehouses, manufacturing, retail, and beyond.

How RFID Sees in Real Time

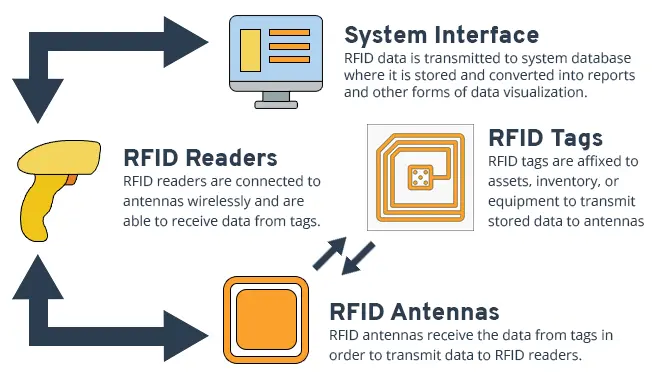

RFID delivers real-time visibility by capturing data automatically as items move through physical spaces—without requiring manual scans or line-of-sight. Each tagged item carries a unique RFID identifier that responds to radio signals emitted by readers placed throughout a facility.

At a high level, here’s how RFID “sees” activity as it happens:

- RFID tags are attached to items, assets, or containers and store a unique ID

- RFID readers and antennas emit radio waves that detect tags as they move through doors, zones, or work areas

- Multiple tags are read at once, even while items are moving

- Each read is time-stamped and sent instantly to backend software

- Systems update location and status in real time, creating a live view of operations

Fixed readers provide continuous coverage at key points like dock doors, conveyors, storage zones, and production areas. Handheld readers complement this setup by supporting cycle counts, spot checks, and exception handling. Together, they create a steady stream of movement data that reflects what’s happening on the floor right now—not hours or days later.

By turning physical movement into immediate digital events, RFID enables systems to truly see inventory, assets, and work-in-process in real time, giving teams the awareness they need to respond faster and operate with confidence.

How RFID Works

How RFID Improves Operations with Real-Time Visibility

Real-time visibility is only valuable if teams can act on it—and that’s where RFID delivers its greatest operational impact. By continuously updating item locations, movement, and status, RFID turns raw data into actionable insight that improves speed, accuracy, and decision-making across the operation.

With RFID in place, organizations can:

- Eliminate blind spots by knowing where inventory, assets, and work-in-process are at any moment

- Reduce manual labor by replacing repetitive scans and searches with automated data capture

- Respond faster to issues such as misplaced items, bottlenecks, or workflow exceptions

- Improve inventory accuracy to prevent stockouts, overstocks, and emergency replenishment

- Optimize workflows by identifying congestion, dwell time, and inefficient movement patterns

- Support better planning with live data instead of delayed or outdated reports

For warehouses, this means faster picking, smoother dock operations, and more accurate fulfillment. In manufacturing, it enables tighter control over material flow and work-in-process. In retail and healthcare, it ensures critical items are available when and where they’re needed.

By replacing assumptions with real-time facts, RFID empowers teams to operate proactively instead of reactively—driving measurable gains in efficiency, reliability, and overall operational performance.

Final Summary

RFID technology has revolutionized inventory management by providing organizations with unprecedented real-time visibility. Through continuous monitoring, accurate tracking, and streamlined operations, businesses can optimize their supply chains, reduce errors, and make informed.

Interested in RFID?

An RFID tracking system can help organizations of all sizes improve their supply chain efficiency. Contact the CYBRA team to schedule a demo today.