Supply chains continue to grow in complexity. As the movement of goods increases, especially over longer distances and through a growing number of touch points, technology is needed to track the journey of these goods so that manufacturers, distributors and retailers have much stronger control over merchandise. Technologies like RFID have stepped in to help stakeholders monitor their goods with greater efficiency and lower cost.

What is RFID?

RFID, or radio-frequency identification, refers to technology that captures data encoded in labels and tags with a reader via radio waves.

RFID technology is similar to a barcode or the magnetic stripe of a credit card, as the data encoded in the label or magnetic strip can be captured by a device and stored in a database.

However, RFID technology is much stronger: it works within a few feet of a scanner and can scan multiple objects at once. A warehouse worker does not need to use a scanner in close proximity to the item, and does not need to scan items one by one. The speed afforded by RFID technologies provides a tremendous advantage to operations that need to scan hundreds or even thousands of goods at once. Additionally, each RFID tag is unique as no two items are alike. This gives supply chains and retailers protection against fraud and counterfeiting.

RFID belongs to a group of technologies referred to as automatic identification and data capture (AIDC). AIDC methods automatically identify objects, collect data about them and enter the data directly into systems with little or no human intervention. RFID methods use radio waves and automation technologies to accomplish all of this. In its simplest form, an RFID system consists of three components: an RFID tag or smart label, an RFID reader and an antenna.

RFID tags contain an integrated circuit and an antenna, which is used to transmit data to the RFID reader (also called an interrogator). The reader then converts the radio waves to a more usable and of course readable form of data. Information collected from the tags is then transferred through a communications interface to a host computer system, where the data can be stored in a database and analyzed later.

RFID Reader

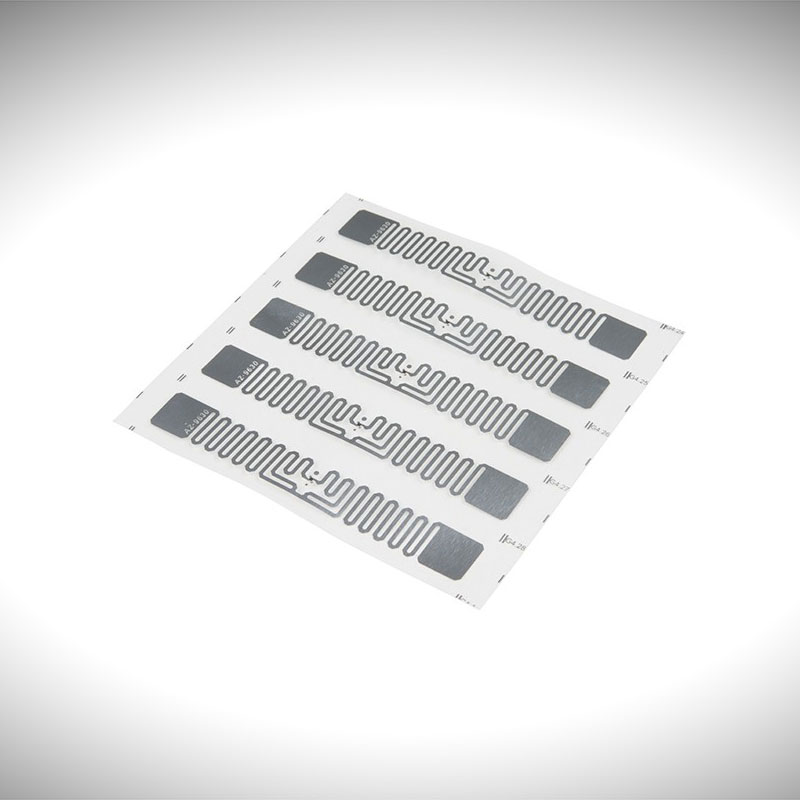

RFID Tag

RFID Tag

An RFID tag consists of an embedded transmitter and a receiver. The tag has two parts: an integrated circuit, or a microchip on which information is stored and processed; and an antenna, used to both transmit and receive signals.

RFID Reader

An RFID reader consists of a transceiver, which is a two-way radio transmitter-receiver. The prime function of the transceiver is to transmit an encoded signal that activates the tag. In response, the tag transponder initiates the conversion of radio signals into usable power along with responding to the reader.

RFID in Supply-Chain Management and Logistics

Supply-chain management and logistics provide the greatest opportunity for applications of RFID technologies. These functions need technology to process large volumes of goods at high speeds.

RFID in the supply chain brings efficiency at every touch point. From the manufacturer to the logistics provider to the warehouse to the retailer to the consumer, RFID technologies enable all participants in this value chain to have the visibility they need to monitor and control the movement of goods.

- RFID solves some of the biggest challenges in supply-chain management and logistics, including:

- Capturing, organizing, storing and analyzing large sums of data

- Reducing labor costs and human error

- Lowering operational costs

- Accelerating the flow of goods

- More effectively using working capital

- Mitigating security risks

- Adhering to regulatory and compliance standards

With RFID systems in place, employees can focus on analyzing data, spotting inconsistencies or taking advantage of opportunities to keep the flow of goods moving from one destination to another.

A Solution for Real-Time Asset Tracking

Edgefinity IoT is an RFID software application built for organizations looking to gain real-time visibility across large industrial environments. Whether you need to track large amounts of inventory, locate misplaced equipment or ensure the safety of your employees, Edgefinity IoT lets you quickly deploy advanced, industrial-strength real-time tracking capabilities. Request a consultation today!

Jake Wengroff writes about technology and financial services. A former technology reporter for CBS Radio, he covers such topics as security, mobility, e-commerce and IoT.

Sources

Supply Chain Brain – How RFID Spreads Benefits Throughout the Supply Chain

Supply Chain – Improving supply chain visibility through RFID