Radio Frequency Identification (RFID) is a wireless technology that uses radio waves to identify and track objects automatically. Unlike traditional barcodes, which require manual scanning, RFID works without line-of-sight and can capture data in bulk, instantly.

From retail and logistics to healthcare and manufacturing, RFID is transforming the way businesses manage inventory, track assets, and improve operations. In fact, adoption is accelerating — industry studies show that more than half of major retailers and nearly half of manufacturers are already using RFID to boost visibility and efficiency.

In this article, we’ll break down what RFID is, how it works, the different types of RFID systems, and why it’s becoming such a powerful tool in the modern supply chain.

Brief History of RFID

RFID’s origins go back to World War II, when radio signals were first used to identify friendly aircraft. In the 1970s, commercial systems appeared for security and toll collection, and by the 1980s and 90s, industries were tracking assets and shipments with RFID. Since the 2000s, falling tag costs and global standards have fueled widespread adoption.

Today, RFID is used to manage inventory, track assets, enable contactless payments, and provide real-time visibility across supply chains, healthcare, and retail.

Core Components

At its core, RFID is a wireless technology that uses radio waves to identify and track items without physical contact. Unlike barcodes, which require line-of-sight scanning, RFID captures data automatically through radio signals.

A complete RFID system has four main components:

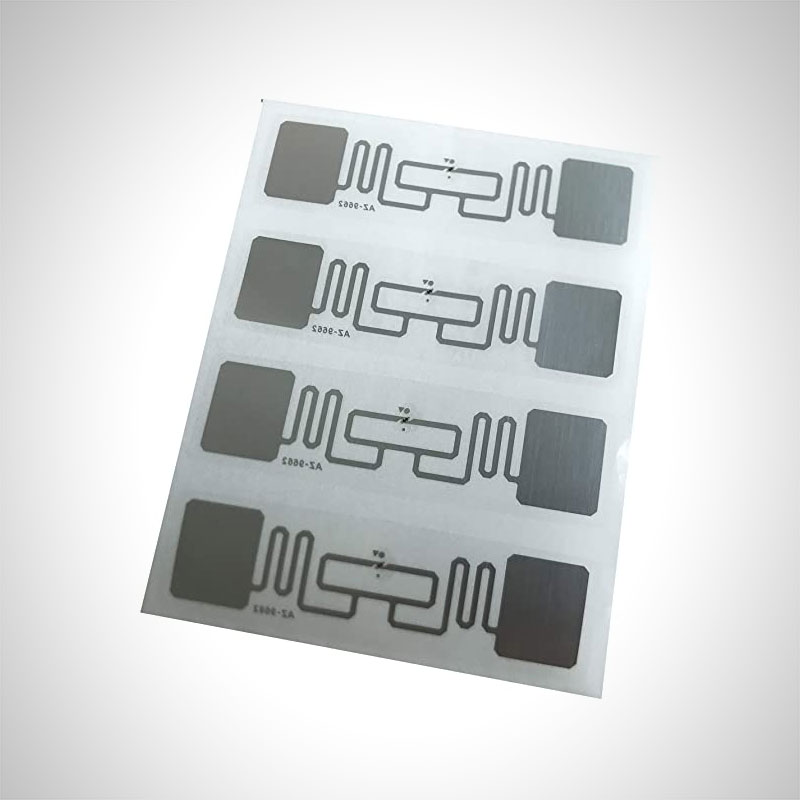

- RFID Tags – small chips with antennas that store data and respond to signals.

- RFID Readers – devices that send and receive radio waves.

- Antennas – the link that carries signals between readers and tags, extending coverage and accuracy.

- Backend Software/Database – where the captured data is processed, stored, and analyzed.

Together, these parts enable RFID to deliver fast, automated, and accurate data capture. In the next sections, we’ll go over each component in detail.

The Limitless Power of RFID

RFID improves inventory accuracy from 63% to over 95%, while reducing cycle count times by up to 96%. In retail, RFID can unlock up to ~5% top-line growth, and sales lifts of 1–5% thanks to better stock availability.

Passive RFID tags

Active RFID tags

Semi-passive RFID tags

Passive RFID Tags

Passive RFID tags do not have an internal power source and rely on radio frequency energy transmitted by RFID readers to power the chip and transmit data. These tags are cost-effective, lightweight, and suitable for short-range applications such as access control, inventory management, and supply chain tracking.

Active RFID Tags

Active RFID tags contain an internal battery that powers the chip and enables longer-range communication with readers. These tags have a higher read range and can transmit data over greater distances, making them ideal for asset tracking, vehicle monitoring, and real-time location systems (RTLS) applications.

Semi-Passive RFID Tags

Semi-passive RFID tags combine elements of both passive and active tags, featuring an internal battery to power the chip while relying on external RF energy for communication. These tags offer enhanced read range and memory capacity compared to passive tags, making them suitable for applications requiring increased data storage and transmission capabilities.

Tag Type Breakdown

| Type | Power Source | Read Range | Cost | Pros | Cons |

|---|---|---|---|---|---|

| Passive RFID | No battery (powered by reader) | Short (cm to ~10 m) | Low | Cheap, small, long life | Short range, weaker signal |

| Active RFID | Built-in battery | Long (100 m–1 km) | High | Long range, strong signal | Expensive, battery limits |

| Semi-Passive RFID | Battery powers chip only | Medium (longer than passive) | Medium | More range, more memory | Higher cost, battery drains |

Curious to know more? Check out our passive vs active RFID page.

RFID Readers

RFID readers — often called interrogators — are the devices responsible for capturing the information stored on RFID tags. They act as the bridge between the physical tag and the digital system where the data is stored and analyzed. Without readers, tags would simply be silent data carriers.

Readers emit radio frequency signals that “wake up” tags in their range. Once energized, the tags transmit their stored information (such as a product ID, serial number, or asset data) back to the reader. The reader then decodes the signal and passes it to the backend system (such as a warehouse management system or ERP) for further processing and use.

Handheld RFID Reader

Fixed RFID Reader

Types of RFID Readers

RFID readers come in two main forms, each designed for different operational needs:

- Fixed Readers – Installed at strategic points like dock doors, conveyor belts, or entryways, fixed readers provide continuous monitoring. They are ideal for high-volume environments where items need to be automatically tracked as they move.

- Handheld Readers – Portable devices that combine a scanner with a screen or mobile computer. Handhelds are perfect for inventory counts, spot checks, or fieldwork where staff move around with the reader.

How Readers Work

Readers operate by transmitting radio waves at specific frequencies, which activate nearby tags. The tags then respond by sending their stored data back to the reader, either by harvesting the energy from the reader’s signal (in passive systems) or by using their own battery power (in active or semi-passive systems).

The reader decodes this response, extracts the information, and passes it on to connected software systems — such as middleware, databases, or cloud applications — where the data can be analyzed, reported, or used to trigger automated workflows.

Antennas and Connectivity

Most RFID readers rely on antennas to direct and receive signals. Some handheld readers have built-in antennas, while fixed readers may connect to multiple external antennas to cover wide or complex areas.

Modern readers also support a range of connectivity options — from Ethernet and Wi-Fi to Bluetooth and cellular — making integration into existing IT systems more seamless.

RFID Frequency Range

RFID systems operate across several different frequency ranges, and the choice of frequency has a major impact on performance, cost, and application. The most common categories are:

- Low Frequency (LF): Around 125–134 kHz, with short read ranges (up to ~10 cm). Works well near water and metal; used for animal tags and access control.

- High Frequency (HF): Typically 13.56 MHz, readable up to ~1 meter. Common in smart cards, library systems, and NFC payments.

- Ultra-High Frequency (UHF): 860–960 MHz, with ranges up to 10+ meters. Fast, scalable, and the most popular for supply chain and inventory tracking.

- Microwave (less common): 2.45 or 5.8 GHz, used in niche cases like toll collection.

In short: LF and HF are best for short-range, specialized use cases, while UHF dominates in logistics and inventory management because of its extended read range and ability to track thousands of items quickly.

RFID Standards and Regulatory Systems

To ensure RFID technology works consistently across industries and countries, several organizations have developed standards and regulatory frameworks. These systems define how tags and readers communicate, which frequency bands are allowed, and how data should be structured.

- EPC (Electronic Product Code): EPC is a universal identifier designed to give each item a unique digital identity. Unlike a traditional barcode that represents a product type, EPCs can distinguish individual items. This makes them vital for tracking products throughout the supply chain.

- EPCglobal: EPCglobal, a joint venture of GS1 and GS1 US, oversees the development of standards for EPC implementation. It defines how EPC data is encoded on tags and how it’s shared between companies using standardized data exchange protocols. EPCglobal standards are widely adopted in retail, logistics, and manufacturing.

- ISO Standards: The International Organization for Standardization (ISO) publishes global standards, such as ISO 18000 series for air interface protocols. These ensure compatibility across different vendors and countries.

- Regulatory Bodies: Governments regulate which frequency bands RFID can use to avoid interference with other wireless systems. For example, the FCC (Federal Communications Commission) manages frequencies in the U.S., while the ETSI (European Telecommunications Standards Institute) does so in Europe. Regional rules may vary slightly (e.g., UHF operates at 902–928 MHz in the U.S. and 865–868 MHz in Europe).

Standards like such as these make RFID data universally understandable, while organizations like ISO, FCC, and ETSI ensure that devices operate legally and consistently across regions.

Applications of RFID

RFID technology finds widespread applications across various industries and sectors, revolutionizing business processes, enhancing operational efficiency, and enabling innovative use cases.

Here are 5 typically applications of RFID:

Inventory Tracking

RFID enables real-time tracking and monitoring of inventory levels, locations, and movements within warehouses, distribution centers, and retail stores. By automating data capture, RFID improves inventory visibility. This helps optimize stock levels, reduce stockouts, and increase supply chain efficiency.

Asset and Equipment Monitoring

RFID is used to track and manage assets, equipment, and tools in industries such as healthcare, manufacturing, and construction. By tagging assets and placing readers in key locations, organizations can monitor usage, prevent loss or theft, and streamline maintenance

Access Control and Security

Access control systems are employed to secure facilities, restrict unauthorized access, and monitor employee movements. RFID workwear, badges, or cards are issued to authorized personnel, enabling seamless entry and exit from restricted areas while maintaining security and compliance with regulatory requirements.

Logistics and Supply Chain Management

RFID plays a critical role in logistics and supply chain management. It enables end-to-end visibility and traceability of goods. Tags are attached to shipments, pallets, and containers, allowing for real-time tracking of cargo, route optimization, and efficient handling of inventory across distribution networks.

Contactless Payments

RFID technology is utilized in contactless payment systems, enabling consumers to make transactions by simply tapping their cards or mobile devices at point-of-sale terminals. This convenience enhances the customer experience, reduces transaction times, and improves payment security by minimizing physical contact with payment terminals.

RFID ROI Calculator

Take the guesswork out of your investment with our ROI calculator. See potential savings and discover how RFID can enhance operations across industries.

Benefits

From retail to healthcare to logistics, RFID delivers far more than just faster scanning. By combining automation, real-time tracking, and accuracy at scale, RFID technology unlocks measurable benefits that help businesses cut costs, improve service, and stay competitive.

%

RFID can cut cycle count times by up to 96%

%

RFID boosts inventory visibility by 60%+

%

RFID pushes inventory accuracy rates to 95%+

%

RFID reduces shrinkage by up to 25%

Improved Efficiency

RFID automates data capture, eliminating manual scans and reducing human error. Studies show RFID can cut cycle count times by up to 96%, allowing staff to focus on higher-value tasks instead of scanning barcodes one by one.

Enhanced Visibility & Traceability

RFID provides real-time visibility of assets and inventory across the supply chain. According to GS1, companies using RFID improve inventory visibility by over 60%, enabling proactive risk management and stronger customer service.

Greater Accuracy

While manual scanning averages 63% inventory accuracy, RFID pushes accuracy rates to 95% or higher. This prevents costly stockouts, mis-shipments, and compliance issues — even in high-speed or challenging environments.

Cost Savings

RFID reduces shrinkage by up to 25%, cuts labor costs through automation, and boosts sales by ensuring products are in-stock when customers need them. The average payback period for RFID projects is 12–18 months, with many businesses reporting millions saved annually in reduced errors and optimized inventory.

Challenges

While RFID technology offers significant advantages, its adoption may also present certain challenges for organizations, including:

Initial Investment Costs

Upfront costs — tags, readers, and backend systems — can be high, especially for large-scale projects. Organizations should weigh ROI and long-term benefits before moving forward.

Integration Complexity

Integrating RFID with WMS, ERP, or inventory systems can be complex, with compatibility, migration, and customization challenges. Careful planning and coordination are key.

Readability and Interference

Ensuring reliable RFID reads can be tricky, with interference from materials, signals, or environments. Poor tag placement or attenuation may cause errors, shorter ranges, or unreliable data capture.

Future Prospects

Despite the challenges, the future of RFID technology appears promising, with ongoing advancements in hardware, software, and standards driving innovation and adoption across industries. Some key trends and developments:

Enhanced Performance

Continued advancements in RFID technology, including improvements in tag design, reader capabilities, and communication protocols, are expected to enhance the performance, reliability, and scalability of RFID systems. This will enable organizations to deploy RFID solutions in a wider range of applications and environments, including challenging or high-speed scenarios.

Internet of Things (IoT) Integration

RFID technology is increasingly being integrated with other emerging technologies, such as the Internet of Things (IoT), to create interconnected ecosystems of smart devices. By combining RFID with IoT platforms, organizations can leverage real-time data insights, predictive analytics, and machine learning algorithms to optimize business processes, improve decision-making, and unlock new opportunities for innovation and growth.

Industry-Specific Solutions

The adoption of RFID technology is expanding beyond traditional applications such as retail and logistics, with growing demand for industry-specific solutions tailored to the unique needs and requirements of various sectors. Industries such as healthcare, manufacturing, automotive, and agriculture are exploring innovative use cases for RFID, including patient tracking, supply chain optimization, quality control, and asset management.

Sustainability and Environmental Impact

RFID technology offers potential benefits in terms of sustainability and environmental impact, enabling organizations to reduce energy consumption, minimize waste, and optimize resource utilization through improved inventory management and operational efficiency. As businesses increasingly prioritize sustainability goals and corporate social responsibility (CSR) initiatives, RFID solutions that contribute to environmental sustainability are likely to gain traction in the marketplace.

Interested in RFID?

An RFID tracking system can help organizations of all sizes improve their supply chain efficiency. Contact the CYBRA team to schedule a demo today.