The automotive supply chain moves fast—and every part must arrive at the right place, at the right time, in the right condition. From raw components to finished vehicles, accurate labeling keeps production lines running. It also ensures full traceability across suppliers, manufacturers, and distributors.

In this article, we’ll explain how car part labeling works across the automotive supply chain. We’ll also explore why standardized labels matter for compliance, efficiency, and visibility.

Why Labeling Matters in the Automotive Supply Chain

Proper labeling is a foundational requirement in the automotive supply chain. Every car part must be clearly identified and traceable as it moves through the supply chain. Without accurate labeling, even small errors can disrupt production lines, delay repairs, or create compliance risks.

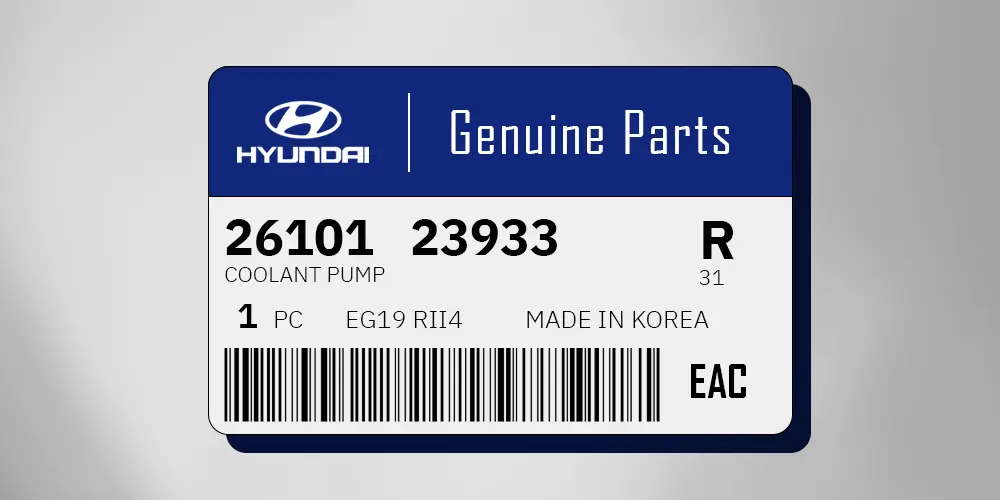

Automotive parts labeling supports accurate identification at every stage—from manufacturing and assembly to installation and aftermarket service. Barcodes and serialized data ensure teams use the correct parts in the correct locations, reducing the risk of mis-installation, incompatibility, or safety issues. Clear labeling also enables faster inspections, recalls, and root-cause analysis when defects or quality issues arise.

Barcode Standards Used to Label Automotive Parts

Labeling systems and barcode printing software are key tools for a car manufacturer’s supply chain. They help to save time, reduce costs and improve accuracy as companies struggle to keep up with ever-increasing customer demand. A common type of barcode for labeling car parts is the 2D barcode. 2D barcodes typically used for labeling car parts are QR codes.

Automotive supply chains also use other barcode types, including Code 128 and Interleaved 2 of 5. Many auto manufacturers have adopted both codes as part of their standard production processes, enabling them to track inventory in real time throughout their operations.

2D barcodes can hold more information than a linear barcode, such as quantity, URLs, part status, or part origin, which make them especially useful in automotive manufacturing environments where detailed tracking is required.

Top 5 Labeling Trends for 2026

In 2026, labeling is no longer just a back-end operational task—it’s becoming a critical driver of compliance, automation, and supply chain visibility.

Regulatory Compliance in Auto Manufacturing

Labeling is equally critical for regulatory compliance. Automotive manufacturers must meet strict industry, safety, and regional requirements, including traceability standards, import/export regulations, and customer-specific labeling mandates. Inconsistent or incorrect labels can result in rejected shipments, audit failures, or costly rework.

Because automotive labeling requirements frequently change—due to new markets, customer specifications, or regulatory updates—labeling must be accurate, flexible, and tightly integrated with production systems. When done correctly, proper labeling keeps parts moving efficiently, protects quality and safety, and ensures compliance across a highly complex global supply chain.

Current Automotive Labeling Regulatory Compliance Requirements

- AIAG B-10 Part Marking Standard — Defines standardized part marking formats and data structures for traceability across suppliers and OEMs.

- ISO/TS 16949 / IATF 16949 Compliance — Mandates consistent labeling and traceability as part of quality management systems for automotive suppliers.

- GS1 Standards Adoption — Requires the use of GS1 identifiers (GTINs, SSCC, GLN) and compliant barcodes or 2D symbols for parts, packaging, and logistics units.

- UDI (Unique Device Identification) for Automotive Safety Parts — Emerging requirements for unique identifiers on critical safety components, similar to medical device UDI principles.

- Import / Export Customs Labeling — Ensures part labels meet destination-country customs and tariff documentation requirements.

- Hazardous Materials (HAZMAT / GHS) Labels — Requires proper labeling for chemicals and hazardous automotive fluids under GHS and local transport regulations.

- OEM-Specific Labeling Mandates — OEMs such as Ford, GM, Stellantis, and Toyota issue proprietary specifications for part marking, data elements, and label placement.

- Environmental & Recycling Labels — Some regions require labels supporting recycling, end-of-life instructions, or material composition disclosures (e.g., EU ELV Directive).

- VIN & Chassis Traceability — Labels include VIN-associated data to support traceability throughout assembly and service life.

- Anti-Counterfeiting Labeling — Uses security features such as QR codes and digital seals to prevent counterfeit parts and protect brand integrity.

Benefits of Modernizing Your Labeling System in Automotive Manufacturing

Modern automotive manufacturing depends on speed, accuracy, and traceability. Updating your labeling system helps ensure every part, container, and shipment carries the right data at the right time—without slowing production.

A modern labeling platform reduces manual data entry and errors by integrating directly with ERP, MES, and WMS systems. Labels update automatically as specifications, customers, or regulations change, helping manufacturers avoid rework, rejected shipments, and compliance issues.

Improved traceability is another key benefit. Advanced barcodes, serialization, and RFID enable manufacturers to track parts across production lines, suppliers, and distribution channels. This visibility supports faster recalls, better quality control, and stronger accountability across the supply chain.

Modern labeling systems also scale with production. Whether launching new vehicle programs, expanding to new markets, or supporting multiple OEM labeling standards, a flexible labeling solution adapts without disrupting operations. The result is faster throughput, lower costs, and a more resilient automotive supply chain.

Choosing the Right Label Printing System for Automotive Manufacturing

The right label printing system helps automotive manufacturers stay compliant, accurate, and efficient at scale. With strict OEM requirements and high production volumes, labels must generate automatically with the correct data—without manual steps or rework.

A modern system should integrate with ERP, MES, and WMS platforms, support multiple barcode and RFID standards, and adapt quickly to changing regulations or customer requirements. Centralized control and easy updates ensure consistency across plants and suppliers.

By choosing a scalable, enterprise-grade labeling solution, manufacturers reduce errors, improve traceability, and keep production moving without disruption.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.