In today’s increasingly digital and fast-paced business environment, organizations are constantly seeking ways to streamline processes, cut costs, and improve overall operational efficiency. One often overlooked but highly critical aspect of this is the management of documents, reports, and information distribution, which can either be in digital form or physical print.

This is where an Output Management System (OMS) comes into play. In essence, an OMS helps manage, control, and optimize how information is delivered, regardless of the output medium, making it an essential tool for enterprises dealing with high volumes of data and document production.

Understanding Output Management Systems (OMS)

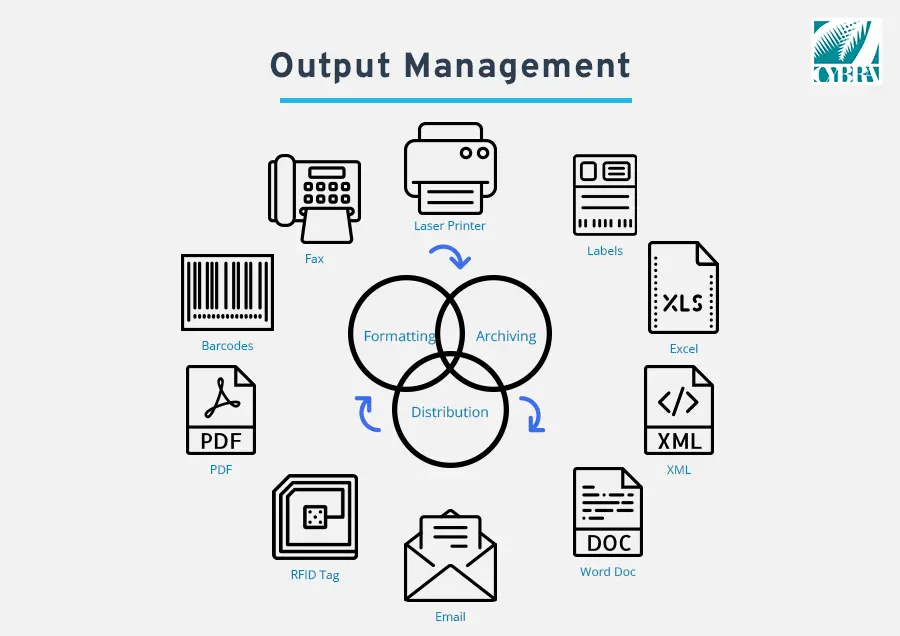

An Output Management System (OMS) is a software solution designed to control the creation, distribution, and management of a company’s output, whether digital or physical. It plays a central role in helping organizations manage the complexity of handling large volumes of documents, reports, labels, forms, invoices, and other critical business communications.

In many businesses, especially those in logistics, retail, manufacturing, healthcare, and finance, timely and accurate document generation and distribution are mission-critical. The OMS ensures that documents are delivered to the correct destination in the right format, be it a digital PDF, an email, or a printed hard copy.

At its core, an OMS bridges the gap between various business applications (like ERP or CRM systems) and output devices, such as printers, fax machines, or digital repositories. By integrating into a company’s existing systems, an OMS improves efficiency, ensures consistency, and reduces the risk of human error.

Moreover, modern OMS solutions typically provide additional functionalities such as data security, compliance with regulations, and tracking and auditing capabilities.

The Role of Enterprise Output Management Systems (EOMS)

When discussing Output Management Systems, it’s essential to highlight the subset known as Enterprise Output Management Systems (EOMS). These are specifically tailored for large-scale organizations that produce vast amounts of documentation, often across multiple departments, locations, or regions. An EOMS helps enterprises manage their complex and decentralized output needs by providing a centralized platform to control and monitor all forms of output.

An Enterprise Output Management System offers numerous benefits:

- Centralized Control: EOMS allows businesses to manage all output types—whether it’s digital, printed, or electronic—through a single platform. This centralization helps reduce inconsistencies and errors, particularly when dealing with vast quantities of documents.

- Compliance and Security: Many enterprises operate in highly regulated industries such as healthcare or finance. An EOMS can help ensure that document handling complies with industry regulations and provides secure channels for sensitive information.

- Cost Efficiency: With a central platform managing printing and digital distribution, enterprises can significantly reduce unnecessary printing costs, optimize the use of consumables (like paper and toner), and ensure efficient printer usage.

- Scalability: Whether a company is printing thousands of shipping labels or managing multi-channel customer communications, EOMS platforms can scale according to the organization’s needs without overhauling the entire system.

Printing in an OMS Environment

While an OMS covers a wide range of output types, including emails, PDFs, or archived documents, the printing aspect remains one of the most prominent uses. Businesses that rely on high-volume printing—such as manufacturers, logistics providers, or retail chains—can see immediate benefits from a robust OMS. These systems can be specifically designed to optimize and control the entire printing workflow, including barcode label printing, RFID tags, and other specialty printing processes.

Barcode Label Printing

Barcode label printing is a vital function in industries like manufacturing, warehousing, and logistics, where tracking products, components, and shipments is critical. A barcode is a machine-readable representation of information about a product or package, and the labels must be produced accurately, at scale, and often in real-time.

An OMS can optimize the process of barcode label printing by:

- Automation: Automatically generating barcode labels based on real-time data from a company’s inventory or supply chain management system. For example, an OMS can integrate with an ERP system to automatically generate a barcode label as soon as a product is added to the inventory.

- Consistency and Accuracy: Ensuring that the correct labels are printed with accurate information, reducing the risk of human error. This is particularly important when dealing with thousands of labels, as a single error can result in costly delays.

- Printer Optimization: Managing the load across multiple printers and ensuring that each device is used efficiently, reducing wear and tear and optimizing printer consumables like labels and ink.

For example, a large warehouse might use an OMS to manage its barcode label printing operations. As products are received and shipped, the OMS ensures that the correct barcode label is printed and attached to the product in real-time, minimizing delays in the supply chain.

RFID Tag Printing

RFID is another important technology that OMS supports. RFID tags are used in industries like retail, healthcare, and logistics for tracking assets, products, and equipment. These tags contain electronically stored information, which can be read by an RFID reader without direct line-of-sight, unlike barcodes. This makes them especially useful in complex environments such as large warehouses, distribution centers, or hospitals where visibility is often limited.

RFID tags are generally printed with human-readable information, barcodes, and electronic data stored within the RFID chip. An OMS plays a crucial role in managing the process of RFID tag printing by:

- Data Integration: Pulling relevant data from enterprise systems to encode the RFID chip with accurate information. This process ensures that the tags are correctly printed and encoded without manual intervention.

- Batch Processing: An OMS can handle large-scale batch printing of RFID tags, which is especially useful when manufacturing or shipping hundreds or thousands of items simultaneously.

- Compliance: For industries like healthcare or aerospace, RFID tags may need to adhere to strict industry standards. An OMS can ensure compliance with these regulations by managing the data encoding process.

For instance, in a retail environment, an OMS could manage the printing of RFID tags for every product in a store. These tags allow for easier inventory tracking, quicker checkout processes, and even loss prevention, as RFID technology can track items throughout the supply chain.

Laser Printer Deployment

Laser printers are widely used in offices and production facilities for printing documents such as invoices, reports, contracts, and letters. In an OMS environment, laser printers can be easily integrated by setting up print queues based on document types and output requirements. The OMS automates printer selection, ensuring that the right printer is used for each job. For example, high-quality laser printers may be selected for printing official documents, while lower-cost printers may be used for internal communications. The system can also distribute print jobs based on location, sending documents to the nearest available printer to reduce printing time and costs.

Document Generation

An OMS effectively automates the generation and printing of various documents, leveraging multiple file formats to streamline workflows and reduce manual effort.

PDF Generation

PDF is a standard format for business documents such as invoices, reports, and contracts. In an OMS environment, data from Word documents, Excel sheets, or XML files can be automatically converted into PDFs, ensuring consistent formatting. The OMS can then print or distribute these PDFs electronically, such as sending an invoice to a customer or printing a report for internal use.

Word Documents

Word documents are commonly used for contracts, letters, and other official documents. An OMS integrates with business systems to pull data and populate Word templates automatically. Once generated, the documents can be printed or converted to PDFs for distribution. This process helps automate tasks like generating personalized letters or client contracts without manual input.

XML Files

XML files facilitate data exchange between systems, such as ERP or CRM platforms. The OMS parses XML data and automatically generates print-ready documents or PDFs, such as purchase orders or shipping notices. This allows for seamless document generation and output based on real-time system data.

Excel and CSV Files

Excel and CSV files are frequently used for data storage and reporting. In an OMS environment, these files can be imported to automatically generate labels, reports, or invoices. For example, shipping information in an Excel sheet can be converted into barcode labels or packing slips. The OMS ensures accurate data handling and reduces manual data entry, speeding up the printing process for large volumes of documents.

By integrating these file formats, an OMS simplifies document handling, ensuring that businesses can efficiently generate, print, and distribute crucial documents.

Output Management System Benefits

The introduction of an Output Management System into an organization offers several clear advantages, especially in businesses where printing plays a significant role. Here are some key benefits:

- Cost Savings: By optimizing printer usage, reducing waste, and minimizing unnecessary printing, an OMS can dramatically reduce the costs associated with printing. It also reduces IT overhead by automating the management of print jobs.

- Efficiency: An OMS speeds up document and label production, ensuring that critical business processes—such as shipping, manufacturing, or billing—are not delayed by printing errors or bottlenecks.

- Accuracy: By automating many aspects of the printing process, an OMS eliminates the risk of human error, ensuring that every document, label, or tag is correct.

- Sustainability: Many organizations are looking for ways to reduce their environmental footprint. An OMS contributes by reducing paper usage, optimizing printer consumables, and cutting down on waste.

An Output Management System is a powerful tool for businesses of all sizes, but it is especially crucial for enterprises that rely on high-volume document and label printing. Whether it’s managing the complexity of barcode labels or ensuring the accuracy of RFID tag printing, an OMS can streamline operations, reduce costs, and increase efficiency across the board.

By integrating with existing business systems and centralizing control over output processes, an OMS helps organizations maintain accuracy, compliance, and cost-effectiveness in their printing and output operations.

Using MarkMagic for Output Management

MarkMagic is a versatile and widely used output management software specifically designed to handle label printing, barcode generation, and RFID encoding across various industries. It integrates seamlessly with ERP, WMS, and other enterprise systems to automate the creation and distribution of labels, forms, and documents. MarkMagic’s ability to support a wide range of output formats, from standard shipping labels to complex RFID tags, makes it a go-to solution for businesses in retail, manufacturing, and logistics that require high levels of accuracy and efficiency in their labeling processes.

One of the standout features of MarkMagic is its intuitive design interface, which allows users to easily create and modify label templates without the need for programming skills. It supports multiple printer types, enabling organizations to streamline their printing operations across different locations and devices. Additionally, MarkMagic helps reduce errors by automating data integration and ensuring that all printed labels and documents are accurate and compliant with industry standards. This makes it an ideal solution for businesses looking to optimize their output management workflows and reduce operational costs associated with printing.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.