Conditional label printing is a dynamic solution that empowers organizations to customize labels based on specific criteria, optimizing accuracy, efficiency, and compliance. This process is particularly valuable in industries like manufacturing, logistics, healthcare, and retail, where products may require different labeling based on various attributes. In this article, we’ll guide you through the steps to deploy Conditional Label Printing, ensuring a seamless integration into your operational workflows.

Understanding Conditional Label Printing

Conditional Label Printing involves customizing labels based on predefined conditions or rules. This allows for dynamic alterations to label content, format, or design depending on specific criteria such as product type, quantity, destination, or any other relevant factor. The goal is to automate label customization, reducing manual efforts and potential errors.

Step-by-Step Guide to Deploy Conditional Label Printing

Here is a step by step guide that will assist you in identifying the right tools for conditional label printing.

Step 1: Evaluate Operational Needs

- Assess Labeling Requirements: Identify the specific criteria that will trigger label customization. This could include product type, quantity, destination, or any other relevant attribute.

- Understand Label Content: Determine which elements of the label need to be dynamically customized. This could include text, graphics, barcodes, and other relevant information.

Step 2: Choose the Right Labeling Software

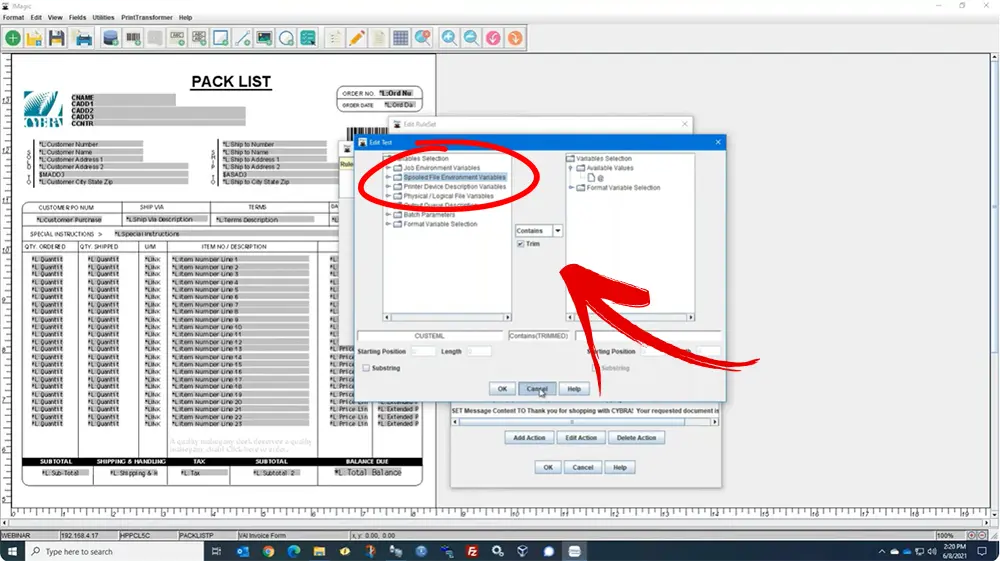

Select a Label Design and Printing Software: Choose a robust labeling software that supports Conditional Label Printing. CYBRA’s MarkMagic is an excellent choice, known for its powerful conditional printing capabilities and ability to import data from a wide range of sources.

Step 3: Design Label Templates

- Access the Label Design Interface: Launch the chosen labeling software and enter the label design interface.

- Create a New Label Format: Begin by creating a new label format or template. Specify the dimensions, orientation, and any other necessary specifications.

- Design the Label Layout: Add elements such as text, graphics, barcodes, and other components that need to be included on the label.

Step 4: Define Conditional Rules

- Access the Conditional Printing Rules Interface: Within your MarkMagic system, navigate to the section for defining conditional printing rules (PrintTransformer).

- Create Conditions: Define the conditions under which specific labels should be printed. For example, set a condition to print a certain label design for products with a specific SKU.

- Link Conditions to Label Formats: Associate each condition with the corresponding label format created in the previous step.

Step 5: Test and Validate

- Simulate Conditional Scenarios: Utilize the simulation feature in the labeling software to test various conditional scenarios. Verify that the correct labels are generated based on the defined rules.

- Validate Data Integration: Ensure seamless integration with your database or data source to retrieve the necessary conditional information.

Step 6: Implement and Monitor

- Deploy in Production Environment: Once testing is successful, deploy the created conditional label printing rules in your production environment.

- Monitor and Fine-Tune: Regularly monitor the system to ensure labels are being generated correctly. Make adjustments to conditions or label formats if needed.

Benefits of Conditional Label Printing

- Enhanced Accuracy: Eliminates the risk of manual labeling errors by automatically generating the correct label based on predefined conditions.

- Improved Efficiency: Streamlines the labeling process, reducing time and resources spent on manual interventions.

- Regulatory Compliance: Ensures that labels adhere to industry-specific regulations and standards, reducing the risk of non-compliance.

- Customization Flexibility: Provides the flexibility to create an array of label designs to meet diverse business needs.

- Cost Savings: Reduces label waste and associated costs by generating labels only when needed.

By deploying conditional label printing, organizations can significantly enhance their labeling processes, leading to improved operational efficiency and accuracy. This powerful solution empowers businesses to meet the unique demands of their industry while ensuring compliance with regulatory standards.

Better Labeling, Better Printing

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.