Asset Tracking for Small Business: Efficiency, Savings, and Growth

For small businesses, effective asset tracking can be a game-changer. The ability to monitor and manage assets efficiently can lead to significant cost savings, improved productivity, and better decision-making. In an era of increasing competition and rapidly evolving...

Using RFID for Personnel Tracking

In high-risk environments like warehousing and utilities, personnel safety is not just a priority—it’s a constant challenge. In fact, warehouse workers face injury rates more than double the national average: 5.5 cases per 100 employees, compared to 2.7 cases across...How to Use RFID to Build an Art Tracking System

A single misplaced artwork can mean more than a missing object. It can trigger insurance claims, damage client trust, delay exhibitions, or erase provenance history built over decades. And the risk is real. More than 50,000 pieces of artwork are stolen or go missing...

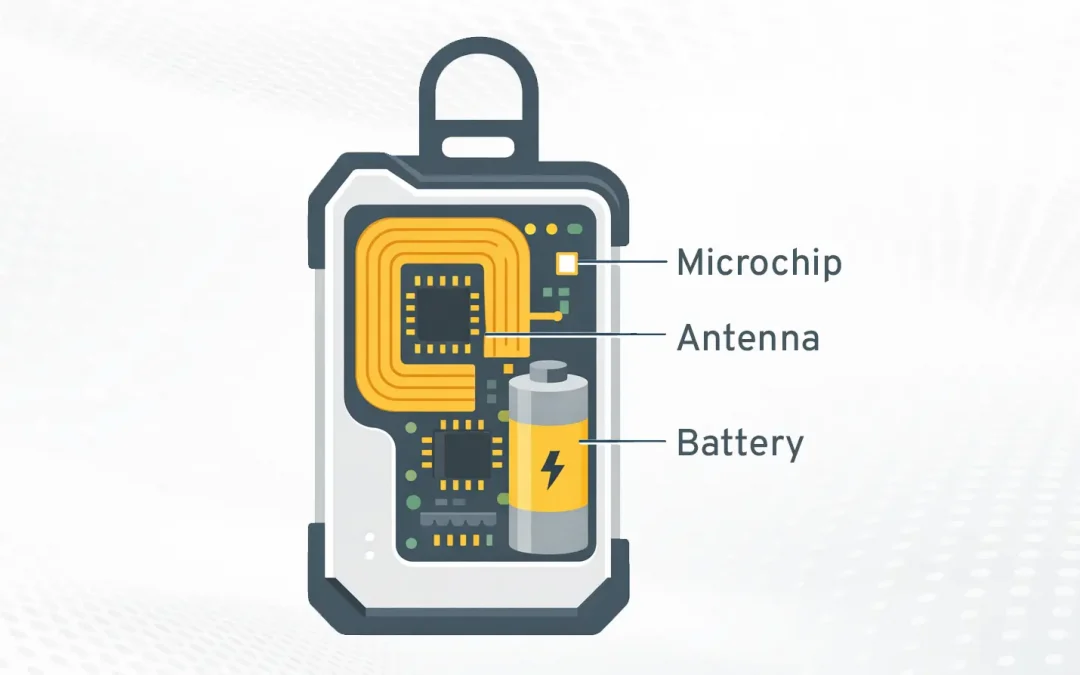

Active RFID: A Complete Guide

Radio Frequency Identification (RFID) technology has revolutionized various industries, and manufacturing is no exception. While passive RFID has been widely adopted for tracking and inventory management, active RFID takes the capabilities to a whole new level. Active...