What’s the difference between active and passive RFID?

- 3/1/25 | Asked by Geoffrey O.

Active vs Passive RFID – What’s the Difference?

When diving into the world of RFID (Radio Frequency Identification), one of the most common questions you’ll encounter is: What’s the difference between passive and active RFID?

It’s a crucial distinction—especially when selecting the right system for your warehouse, manufacturing floor, retail operation, or supply chain. Choosing the wrong one can mean overspending on features you don’t need—or worse, missing out on critical functionality.

Here is the simple breakdown:

- Passive RFID: Tags without a battery, activated by reader signal. Best for inventory, asset tracking, access control.

- Active RFID: Tags with a battery that broadcast signals. Ideal for real-time tracking over long distances.

But as you can imagine, there is a lot more to it than that. Let’s take a deeper dive into what active and passive RFID are, their use cases, and which one might work for your upcoming RFID project.

Active RFID

Passive RFID

Passive vs Active RFID: A Side-by-Side Comparison

Here’s a quick reference table to help visualize the core differences:

| Feature | Passive RFID | Active RFID |

|---|---|---|

| Power Source | No battery – powered by reader signal | Internal battery |

| Read Range | Short (typically 1-30 feet) | Long (100+ feet; up to 1,000 in some cases) |

| Tag Size | Smaller and lighter | Larger due to battery |

| Lifespan | ~20 years (limited only by tag durability) | Battery-dependent (usually 3-5 years) |

| Cost per Tag | Low ($0.10–$1.00) | Higher ($15–$50+) |

| Typical Use Cases | Inventory, file tracking, retail, access | Vehicle tracking, equipment monitoring, RTLS |

| Data Storage | Limited (ID, small metadata) | Can store more data and even sensor readings |

What is Passive RFID?

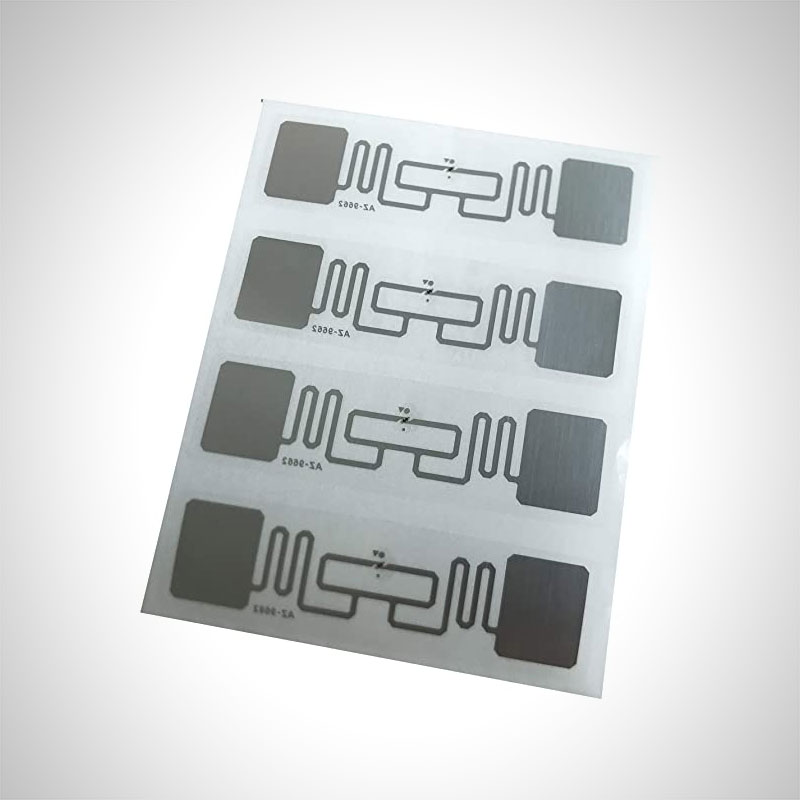

Passive RFID tags are the most common type of RFID technology found in commercial and industrial applications. These tags don’t have a battery—instead, they draw power from the electromagnetic energy emitted by an RFID reader. When the reader sends a signal, the tag captures that energy just long enough to respond with its stored data. Because of this design, passive tags are typically smaller, lighter, and significantly less expensive than their active counterparts.

You’ll often find passive RFID used in retail inventory systems, where it helps track clothing, footwear, and accessories throughout the supply chain. Despite the lower cost, passive RFID systems offer impressive durability and can last for many years, limited mostly by the wear and tear of the tag itself rather than any internal components.

Common Passive Use Cases

- Retail inventory (apparel, shoes, accessories)

- Pharmaceutical supply chain

- Library systems and file tracking

- Pallet and case-level tracking

- Event ticketing and access control

That said, passive RFID comes with some trade-offs.

| Pros | Cons |

|---|---|

| ✅ Cost-effective ✅ Small and flexible form factors ✅ Long shelf life ✅ Easy to scale |

⚠️ Shorter read range ⚠️ Requires proximity to a reader ⚠️ Less suited for real-time location tracking ⚠️ Easily disrupted RFID signals |

What is Active RFID?

Unlike passive tags, active RFID tags come equipped with an internal battery, which allows them to broadcast signals at regular intervals. This built-in power source significantly extends their range—some active tags can transmit data from hundreds or even thousands of feet away. This makes active RFID the go-to choice for use cases where real-time location tracking or long-range visibility is critical.

Common Active Use Cases

- Vehicle fleet tracking

- Equipment and machinery monitoring

- High-value asset tracking

- Real-Time Location Systems (RTLS)

- Cold chain and condition monitoring (with sensors)

Here are some of the main trade-offs for active RFID:

| Pros | Cons |

|---|---|

| ✅ Long read range ✅ Works without constant reader presence ✅ Can include sensors (temperature, vibration, etc.) ✅ Real-time visibility |

⚠️ Higher cost ⚠️ Larger and heavier tags ⚠️ Batteries need replacement |

What is Semi-Passive RFID?

There is actually a third type of RFID—semi-passive RFID. While similar to passive RFID, semi-passive tags include a small battery that powers the tag’s circuitry. This enables longer read ranges and supports additional features such as temperature, humidity, or shock sensors. Unlike active tags, the battery doesn’t power continuous broadcasting—it simply boosts performance when the tag is energized by a reader.

Semi-passive RFID is particularly valuable in large-scale inventory systems and specialized environments like cold chain logistics, pharmaceuticals, or high-value electronics, where tracking both location and condition is critical. These tags strike a balance between cost and capability: more affordable than fully active RFID, but with far more functionality than passive options.

Choosing the Right System

When deciding between passive and active RFID, start by assessing your environment. If you’re working within a small, controlled space—like a retail store, backroom, or warehouse shelf—passive RFID is usually the better fit due to its low cost and minimal infrastructure requirements. On the other hand, if your operation covers a large facility, yard, or outdoor space where assets move constantly, active RFID will give you the range and real-time tracking you need.

It’s also smart to consider the value of the items you’re tracking. Passive RFID is great for high-volume, lower-cost goods like apparel or packaging, while active RFID is best reserved for high-value assets such as vehicles, tools, or machinery.

Think about read range needs too: if you’re scanning items at close range during receiving or picking, passive works well; but if you need to monitor movement throughout an entire facility, active is your go-to.

Lastly, factor in infrastructure—passive systems may require more readers placed throughout the space, whereas active systems can often get by with fewer receivers placed strategically.

💡 Quick tip: When choosing between active and passive RFID, start by mapping your use case. If you need real-time tracking over long distances (like vehicles, containers, or large equipment), active RFID is often worth the investment. For high-volume, low-cost tagging (like pallets, cases, or retail items), passive RFID delivers the best ROI.

Real World Examples

Here are a few real world use cases for RFID and which system to use:

| Scenario | Recommended RFID Type |

|---|---|

| Inventorying boxes on shelves | Passive RFID |

| Tracking forklifts and pallet movement | Active RFID |

| Monitoring temperature-sensitive shipments | Active RFID (with sensor) |

| Managing returns and cycle counts | Passive RFID |

| Tracking tools across multiple job sites | Active RFID |

| Managing rental equipment returns at a depot | Passive RFID |

| Monitoring temperature of perishable goods in transit | Active RFID (with sensor) |

Final Thoughts

The right RFID solution depends on your specific operational needs. If you’re looking for a cost-effective way to track lots of small items in a controlled space, passive RFID is your best bet. If you need real-time visibility across a large area—especially for high-value assets—active RFID is the way to go.

Still not sure which is right for you? A hybrid approach might be your best move. Many modern facilities use passive tags for inventory and active tags for equipment or vehicle tracking—getting the best of both worlds.

Need Help Getting Started?

Want help designing the right RFID system for your operation? Drop us a line—our experts are ready to help you tag, track, and take control.