Did you know barcodes are over 70 years old? It’s true. The process of visualizing data through barcode was initially developed way back in 1948. And since then barcodes have become an integral part of virtually every industry in the world. Barcodes have revolutionized the way businesses manage inventory, track products, and streamline operations.

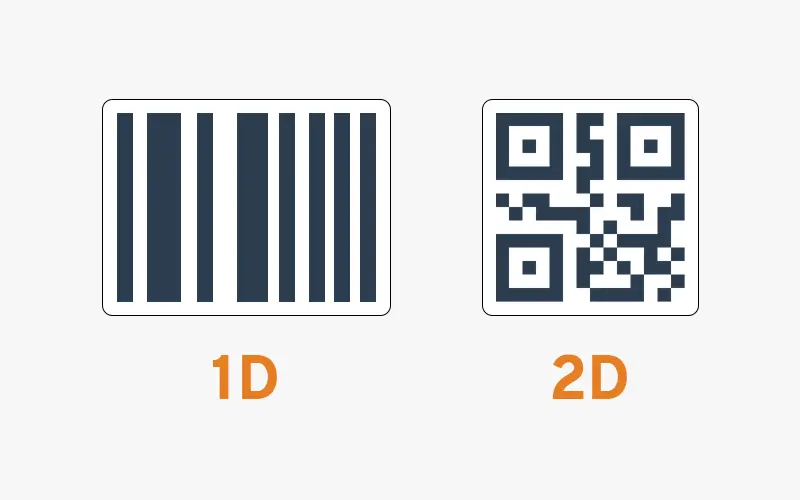

Over the years barcodes have evolved and branched off into several variants. While many consumers may be familiar with the classic UPC barcode, also known as a 1D barcode, there are many other kinds of barcodes that serve as vital checkpoints in various industries and supply chains. Matrix barcodes, also known as 2D barcodes, offer dynamic ways to represent and store data.

In this article we’ll compare and contrast 1D and 2D barcodes in order to understand when specific barcodes are ideal for certain situations.

1D Barcodes

1D barcodes, also known as linear barcodes, are the traditional and most widely recognized form of barcodes. They consist of a sequence of parallel lines and spaces of varying widths, often referred to as bars and spaces, respectively. The Universal Product Code (UPC) and the International Article Number (EAN) are common examples of 1D barcodes.

1D barcodes encode alphanumeric information, typically limited to a set number of characters. They are read using laser scanners or barcode readers, which detect the widths of the bars and spaces to decipher the encoded data. Each barcode represents a unique identifier associated with a specific product or item.

2D Barcodes

2D barcodes, on the other hand, represent a more advanced barcode technology that can store significantly more data compared to 1D barcodes. Instead of using only vertical lines, 2D barcodes incorporate both horizontal and vertical patterns, forming a square or rectangular matrix of dots, squares, or hexagons. Examples of 2D barcodes include Quick Response (QR) codes, Data Matrix, and Aztec codes.

2D barcodes use patterns of dots or squares to encode data, allowing them to store a wealth of information, including text, numbers, URLs, and even multimedia content. They can be read by specialized 2D barcode scanners or smartphone cameras equipped with barcode scanning apps.

Key Differences and Advantages

1D and 2D barcodes differ significantly in how much data they store, how they’re scanned, and where they’re best used. While 1D barcodes are simple, cost-effective, and widely supported, 2D barcodes offer greater data capacity, error correction, and flexibility.

| Feature | 1D Barcodes | 2D Barcodes |

|---|---|---|

| Data capacity | Limited (typically numeric or short alphanumeric) | High (hundreds to thousands of characters) |

| Data format | Linear (horizontal lines) | Matrix (dots, squares, or patterns) |

| Examples | UPC, EAN, Code 128 | QR Code, Data Matrix, PDF417 |

| Scanning direction | One direction (horizontal) | Multiple directions (omnidirectional) |

| Error correction | Minimal or none | Built-in error correction |

| Label size efficiency | Requires more space for more data | Stores more data in a smaller space |

Applications and Use Cases

Barcodes play a crucial role in various industries, streamlining processes and improving efficiency. Both 1D (one-dimensional) and 2D (two-dimensional) barcodes are widely used, each offering specific advantages that cater to different applications. Here’s a breakdown of applications and use cases for 1D and 2D barcodes:

1D Barcodes Use Cases

1D barcodes are widely used for simple, reliable identification and tracking across manufacturing, warehousing, retail, and distribution environments. They encode limited data—such as SKUs or item numbers—but integrate easily with existing systems, making them cost-effective and efficient for high-volume operations.

Organizations commonly use 1D barcodes to automate routine processes, improve accuracy, and reduce manual data entry at key operational checkpoints.

Common 1D barcode use cases include:

- Product identification and tracking using SKUs or item numbers

- Inventory management for receiving, stocking, and cycle counting

- Pricing and point-of-sale (POS) scanning for fast transactions

- Shipping and receiving verification and shipment tracking

- Batch and lot tracking for manufacturing and expiration control

- Asset management for tools, equipment, and machinery

- Order picking and fulfillment to improve accuracy and speed

Free Barcode Generator →

Generate scannable barcodes in seconds. Download the barcode image and import it directly into MarkMagic to use across labels, electronic forms, and reports.

2D Barcodes Use Cases

2D barcodes are designed for applications that require richer data, serialization, and advanced traceability. Unlike 1D barcodes, 2D barcodes can store large amounts of information directly in the symbol, making them ideal for environments that demand real-time visibility, compliance, and detailed product history.

Organizations use 2D barcodes to support complex workflows, improve accuracy across multiple process steps, and enable end-to-end traceability throughout the supply chain.

Common 2D barcode use cases include:

- Advanced product identification and tracking using serial numbers, batch data, and manufacturing details

- Inventory management with real-time updates for receiving, picking, and cycle counts

- Asset tracking for equipment, tools, and machinery

- Quality control and inspection to validate process steps and detect defects

- Order fulfillment and shipping to ensure accurate picking, packing, and routing

- Work-in-progress (WIP) tracking to monitor production flow and identify bottlenecks

- Recall and warranty management to quickly trace affected products and take corrective action

Modernizing Your Barcodes

As barcode requirements evolve, compliance is becoming just as important as functionality. GS1 Sunrise 2027 marks a major shift toward wider adoption of 2D barcodes—such as QR Codes and Data Matrix—at retail point of sale. These next-generation barcodes can carry far more information than traditional 1D codes, supporting serialization, batch data, expiration dates, and traceability without changing label size.

At the same time, GS1 Digital Link is redefining how barcodes connect physical products to digital information. By embedding web-enabled links directly into 2D barcodes, organizations can support regulatory requirements, enable product recalls, share sustainability data, and deliver richer consumer experiences—all from a single code.

As regulations tighten and supply chains demand greater transparency, 2D barcodes are becoming the preferred foundation for future-ready, GS1-compliant labeling strategies.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.