In early 2022, Walmart announced a major expansion of its RFID program, extending item-level tagging requirements beyond apparel into additional departments such as home goods, sporting goods, electronics, and toys. As the world’s largest retailer, Walmart’s continued investment in RFID has far-reaching implications for manufacturers, distributors, and suppliers across its ecosystem.

Since that initial expansion, Walmart has steadily broadened its RFID requirements. Additional general merchandise categories went live in early 2024, with further rollouts continuing through 2025 and beyond. Rather than a one-time initiative, Walmart now uses RFID as a foundation for its long-term inventory and fulfillment strategy.

Any organization doing business with Walmart must now treat RFID as an ongoing operational requirement—not a temporary compliance project.

Article Highlights

- Walmart continues to expand its RFID mandate across apparel, hardlines, and general merchandise categories, with additional requirements rolling out through 2025 and beyond.

- Many general merchandise categories now require item-level RFID tagging, not just apparel.

- Walmart requires RAIN RFID (EPC Gen 2v2) tags operating in the 902–928 MHz range.

- RFID inlays must be sourced from Auburn University ARC-approved manufacturers and tested for performance.

- RFID programs routinely deliver 95%+ inventory accuracy and can reduce out-of-stocks by up to 50%.

- Compliance now extends beyond tagging to include data quality, serialization, and system integration.

- Successful suppliers pilot early, validate tag placement, and embed RFID processes into daily operations.

What is RFID?

RFID, or Radio Frequency Identification, plays a pivotal role in the retail industry, revolutionizing inventory management, supply chain logistics, and customer experiences. Unlike traditional barcodes, RFID tags store electronic data that RFID readers capture wirelessly, enabling real-time tracking. Here are some statistics and facts about RFID usage in the retail industry:

- Enhanced Inventory Accuracy

- Reduced Out-of-Stocks

- Improved Operational Efficiency

- Omnichannel Integration RFID

- Loss Prevention

RFID technology serves as a powerful tool for loss prevention and shrinkage reduction in retail environments. By accurately tracking the movement of items, RFID helps retailers identify and mitigate instances of theft, unauthorized removal, or misplacement of merchandise.

Why RFID is a Top Technology for Retail

RFID enhances the overall shopping experience for customers by ensuring product availability, reducing wait times at checkout, and enabling personalized services such as inventory lookup, product recommendations, and self-checkout options.

Industry Adoption of RFID

RFID adoption in the retail industry continues to accelerate as retailers embrace automation and real-time inventory visibility to compete in omni-channel markets. According to industry research, the global retail RFID market was valued at approximately USD 13.46 billion in 2024 and is projected to grow at a CAGR of about 8.9 % through 2033, reaching nearly USD 29 billion as retailers expand use cases and capabilities.

Retailers are increasingly investing in RFID to improve accuracy and customer experiences. A widely cited Accenture survey found that 93% of North American retailers use RFID technology in some capacity, with full adopters reporting meaningful returns on inventory visibility and omnichannel performance.

RFID systems enable faster cycle counts, reduce stockouts, and support services like buy-online-pickup-in-store (BOPIS) and ship-from-store fulfillment, helping businesses keep pace with rising consumer expectations in a competitive marketplace.

Free RFID Consultation

Have you been handed an RFID mandate? Let us help! We’ve been working with companies to help them leverage RFID implementation mandates, and identify ways they can benefit from RFID.

Key solutions include:

- Tracking and tracing inventory and goods.

- Preventing items from unauthorized usage.

- Ensuring equipment is not taken off premises.

- Check where items are stored for quick finding.

Walmart’s RFID Guidelines

Walmart’s approach to supply chain management has consistently set industry standards, with RFID (Radio Frequency Identification) technology being a key component.

The company’s guidelines for RFID implementation, as outlined in their comprehensive Supply Chain Packaging Guide, are designed to enhance inventory accuracy, streamline processes, and ensure seamless integration into their extensive supply chain network.

This summary highlights the critical aspects of Walmart’s RFID guidelines, focusing on the requirements for different product categories, tag application, and compliance standards.

RFID Requirements for Product Categories

Walmart mandates the use of RFID tags across various product categories, particularly in apparel and hardline departments. All apparel items shipped to Walmart U.S. stores require RFID tags, with specific exclusions for certain eCommerce-only brands and items where RFID technology is incompatible.

The categories requiring RFID tagging include a broad range of apparel, from men’s and women’s wear to accessories, as well as hardlines like toys, sporting goods, and electronics.

RFID Tag Application Guidelines

Walmart’s guidelines provide detailed instructions on how RFID tags should be applied based on packaging type. The general rule is that RFID tags must be integrated into the packaging in a way that ensures readability without compromising the product’s packaging integrity.

For example, RFID inlays should be embedded in branded hangtags or applied as separate stickers depending on the packaging type. Notably, embedding RFID tags directly into the product (such as sewing them into apparel) is strictly prohibited .

The document also specifies placement restrictions to avoid interference with the tags’ functionality. For instance, RFID tags should not be placed at the bottom of poly bags or near metal objects that could disrupt signal transmission.

Example of an EPC combo sticker

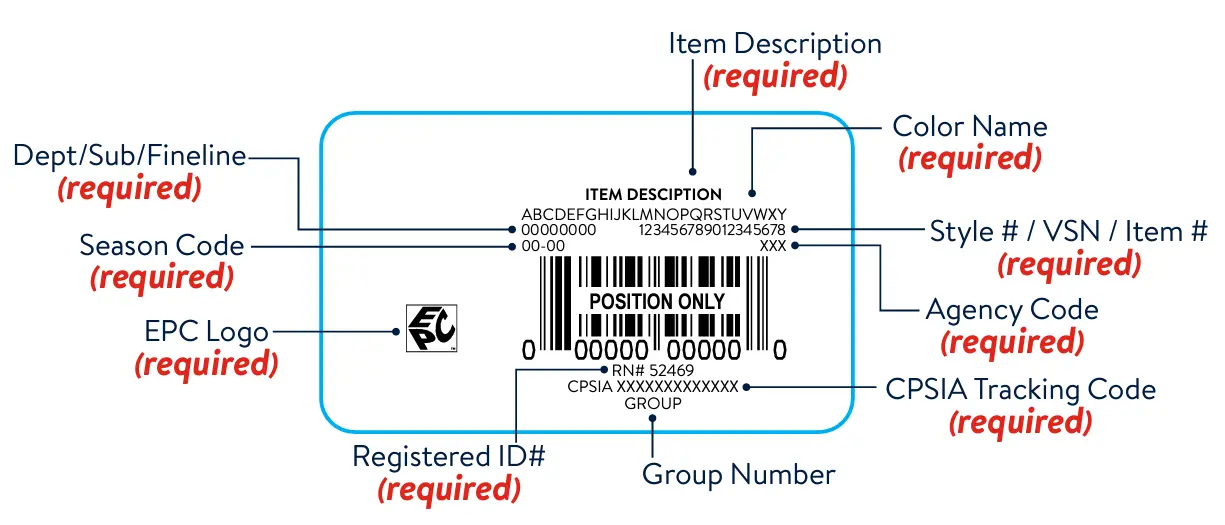

Compliance and Quality Assurance

To ensure the quality and consistency of RFID tags, Walmart requires that all RFID inlays come from Auburn University-approved manufacturers. Even when using an approved supplier, samples must be submitted to Auburn for final approval before being deployed in the supply chain. This stringent process helps maintain the integrity of Walmart’s RFID program, ensuring that all tags are correctly encoded and free of duplication errors .

Walmart also emphasizes the importance of displaying the Electronic Product Code (EPC) symbol on all packaging containing an RFID tag. This symbol must be prominently placed where it is easily visible to both customers and store associates, ensuring that the presence of RFID is clearly communicated.

In addition to physical tag performance, Walmart now places increased emphasis on data accuracy and consistency. Suppliers must ensure correct EPC encoding, avoid duplicate serializations, and maintain reliable read performance throughout distribution and store environments. RFID data is expected to integrate cleanly with backend ERP, WMS, and compliance systems to support real-time inventory visibility.

Impact on Supply Chain Efficiency

The adoption of RFID technology in Walmart’s supply chain brings numerous benefits, including enhanced inventory accuracy, faster processing times in distribution centers, and better product visibility throughout the supply chain.

By following Walmart’s detailed guidelines, suppliers can ensure their products integrate seamlessly into this high-efficiency system, ultimately leading to better product availability and reduced operational costs.

What Are the RFID Tag Specifications?

Walmart requires suppliers to use RAIN RFID tags compliant with EPC Gen 2v2 standards, operating in the 902–928 MHz UHF band. Tags must be encoded using GS1-compliant EPC structures and meet performance thresholds validated by Auburn University’s RFID Lab.

These kinds of tags have a frequency of 902-928 megahertz. Tag dimension requirements will vary depending on the item’s department.

According to Walmart’s Supply Chain Standards Guide:

Brand owners may select any Auburn University-approved inlay manufacturer listed on their website. Any inlay manufacturer not listed on the Auburn website cannot produce inlays for packaging being shipped to Walmart. Even if using an approved inlay provider, you must still submit samples to Auburn for final approval.

Here is how the tag specs are broken down according to Auburn University’s RFID program.

ARC Certification

All Walmart suppliers are required to secure certification for their RFID tags from the RFID Lab at Auburn University, known as the Auburn Renewal Center (ARC). Established in 2009, the ARC program verifies that RFID tags adhere to or surpass the retailer’s performance standards. The program is utilized by roughly a dozen retailers nationwide, as well as by various manufacturers and other entities.

The implementation of this RFID mandate has occurred in stages, with compliance deadlines varying according to product category. The most recent categories required to comply are additions to those already designated for inclusion in the program.

Key Dates and Deadlines

Here are a few dates to keep in mind while you and your team prepares for Walmart’s RFID compliance mandate.

- June 3rd 2022 – Deadline to submit RFID tag samples to Auburn University.

- August 17th 2022 – All RFID-tagged products must arrive to its respective distribution center or facility.

- September 2nd 2022 – All products that are going to stores must be tagged.

- February 1st 2024 – Compliance mandates expand to general merchandise categories

To learn more about Walmart’s RFID packaging expectations, download their supply chain standards document.

How CYBRA’s RFID Experience Can Help

CYBRA’s expertise with RFID technology goes back nearly 20 years. Rely on our experience and scar tissue to help guide your organization through your RFID installation process. Request a free consultation today!