As organizations scale, labeling quickly becomes more complex than simply printing barcodes. Enterprise labeling is designed to support high-volume, multi-location operations where accuracy, consistency, and compliance are critical. From manufacturing and warehousing to healthcare and retail, enterprise labeling ensures the right data appears on the right label—every time, everywhere.

In this article, we’ll explain what enterprise labeling is, how it works, and why it plays a vital role in supporting automation, regulatory compliance, and real-time visibility across today’s connected supply chains.

What is Enterprise Labeling?

Enterprise labeling is a centralized approach to designing, managing, and printing labels across an entire organization. Unlike basic labeling tools that operate in silos, enterprise labeling connects labeling processes directly to business systems—ensuring accuracy, consistency, and scalability across multiple locations, users, and use cases.

At its core, enterprise labeling allows organizations to control label templates, data sources, and printing rules from a single platform. Labels are generated automatically using real-time data from systems like ERP, WMS, MES, or TMS, reducing manual entry, errors, and rework.

Key characteristics of enterprise labeling include:

- Centralized label management – Design and maintain label templates in one system and deploy them globally

- System-driven data – Pull live data from ERP, WMS, MES, and other enterprise platforms

- High-volume, high-speed printing – Support production, warehouse, and shipping operations at scale

- Compliance and validation – Enforce industry standards such as GS1, FDA, UDI, GHS, and customer-specific requirements

- Multi-site consistency – Ensure every facility prints the same compliant labels, regardless of location

- Flexible output – Print barcodes, RFID labels, tags, and documents across thermal, laser, and industrial printers

By standardizing labeling at the enterprise level, organizations eliminate bottlenecks, reduce risk, and create a reliable foundation for automation and real-time visibility across the supply chain.

Why Enterprise Labeling is More Important than Ever

According to a study by Gartner, 80% of companies worldwide expect regulatory complexity to increase in the next three years. Enterprise labeling tools have become indispensable in handling compliance issues.

But it’s not just due to increased regulatory complexity – rising consumer demands, supply chain disruptions, e-commerce growth, and emerging technologies all contribute to the ever-growing need for organizations to make sure their labeling operations are running more efficiently and can handle sudden changes.

Enterprise labeling software combines compliance labeling with cost-effective solutions. A company can manage compliance labeling, product variants, and more with the help of enterprise labeling software. It is essential to integrate enterprise labeling software with existing enterprise applications and key data sources. This will help automate labeling processes and avoid costly mislabeling.

Top 5 Labeling Trends for 2026

In 2026, labeling is no longer just a back-end operational task—it’s becoming a critical driver of compliance, automation, and supply chain visibility.

5 Features Your Enterprise Labeling Software Should Have

In today’s multi-faceted and dynamic supply chain, labeling has never been more important. It is one of the most crucial links in the entire manufacturing/distribution process. Here are a few enterprise labeling software features your system should offer your organization.

1. Powerful Label Design

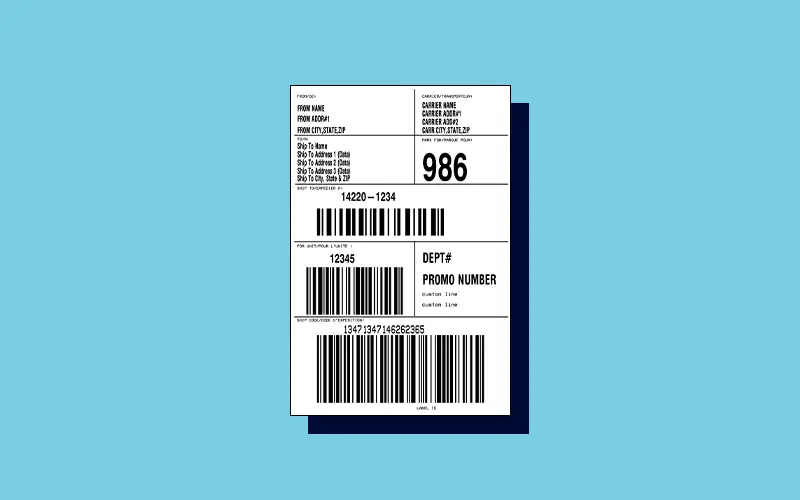

Enterprise labeling software should allow you to create and design labels that are visually appealing and easy to read. This includes the ability to add text, images, barcodes, and other graphics.

2. Data integration

Enterprise labeling software should be able to integrate with your existing data sources, such as your ERP system or CRM system. This allows you to automatically populate labels with data from your existing systems.

3. Scalable Printing

Enterprise labeling software should allow you to print labels in a variety of formats, including thermal transfer, direct thermal, and laser. It should also allow you to print labels in bulk, which can save you time and money.

4. Label Data Management

Enterprise labeling software should allow you to manage your labels, including creating and editing label templates, assigning labels to products or jobs, and tracking label usage.

5. Security

Enterprise labeling software should be secure to protect your data. This includes features such as user authentication, data encryption, and access control.

Picking the Right Enterprise Labeling Software

Choosing the right enterprise labeling software is a strategic decision that directly impacts accuracy, compliance, and operational efficiency. As labeling touches nearly every part of the supply chain—from manufacturing and warehousing to shipping and compliance—the solution must scale with your business and integrate seamlessly with existing systems.

The right platform should centralize label design and governance, connect directly to ERP, WMS, MES, and TMS data, and support high-volume printing without manual intervention. It should also adapt quickly to changing regulations, customer requirements, and new product lines—without disrupting operations.

Equally important, enterprise labeling software must support a wide range of barcode and RFID standards, printers, and deployment models while maintaining strict control over data quality and versioning.

By selecting a flexible, system-driven labeling solution, organizations reduce errors, improve traceability, and ensure consistent, compliant labeling across every facility and partner in their network.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.