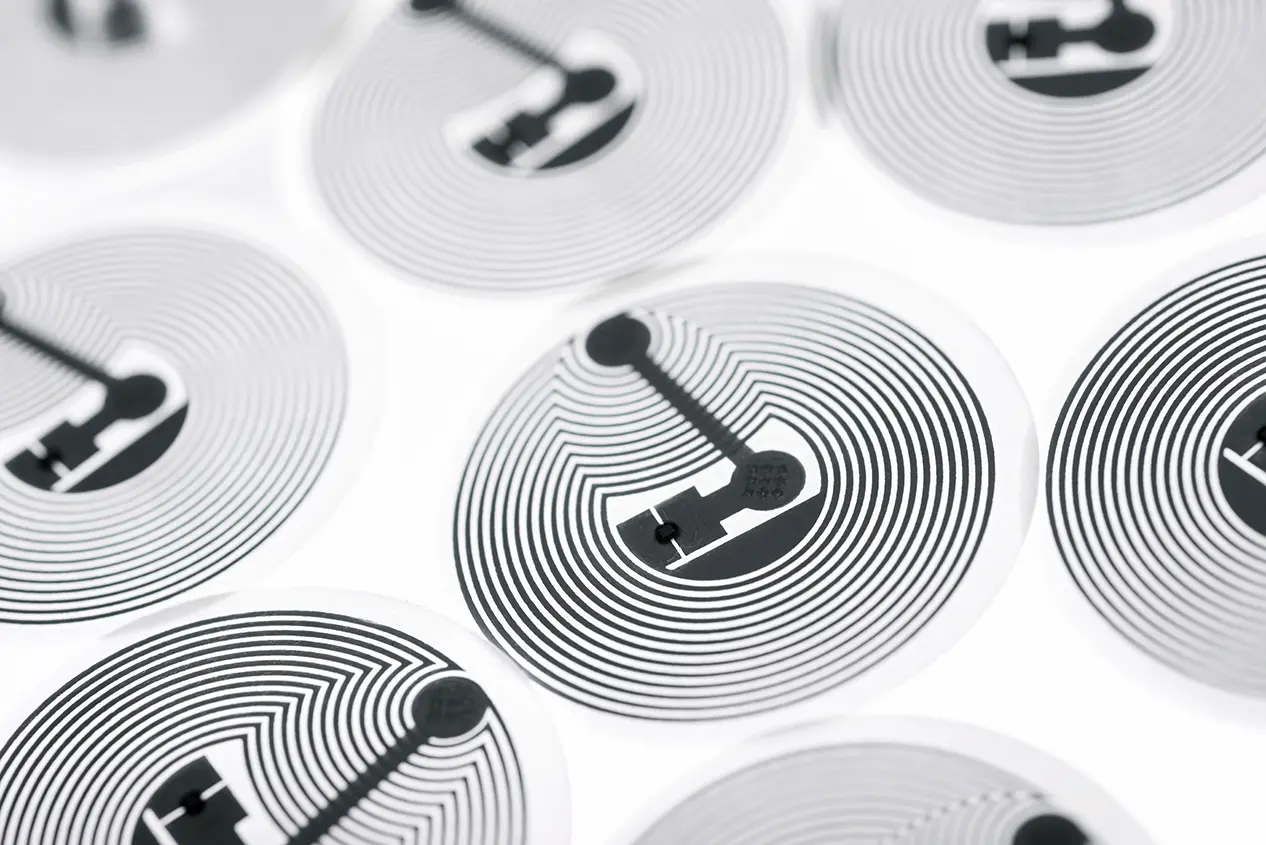

RFID technology makes it possible to track inventory, assets, and products in real time — without line-of-sight scanning. But before an RFID tag can do its job, it must be properly encoded with unique data.

Whether you’re tagging pallets in a warehouse, garments in retail, or components in manufacturing, here’s a step-by-step guide on how to encode RFID tags correctly.

What Does “Encoding” an RFID Tag Mean?

Encoding an RFID tag means writing data into the tag’s memory — typically into the EPC (Electronic Product Code) memory bank.

The EPC acts as the tag’s unique digital identity. Once encoded, that tag can be read by RFID readers anywhere in your facility.

Most UHF RFID tags contain:

- EPC memory (stores the unique ID)

- TID memory (factory-programmed chip ID)

- User memory (optional additional data storage)

For most supply chain applications, encoding focuses on the EPC memory.

Start Using RFID with Minimal Investment →

CYBRA’s RFID starter kit built for simplicity. Perfect for small projects or proof-of-concepts, EdgeMicro lets you bring RFID into your supply chain with less cost, less risk, and faster results.

Choosing the Right RFID Tag

Not all RFID tags are the same. Your environment determines what type you need:

- Label-based RFID tags – Ideal for cartons, cases, and retail items

- On-metal RFID tags – Designed for metal surfaces

- Rugged tags – For industrial or outdoor environments

When selecting RFID tags, make sure they are UHF — the most commonly used frequency for supply chain applications — and fully compatible with your specific printer or encoding hardware. It’s also important to verify that the tags are certified for any retailer mandates or compliance programs you’re participating in, ensuring they meet required performance and data standards.

Defining Your Data Structure

Before encoding, determine what data the tag will contain.

Common formats include:

- SGTIN-96 (Serialized Global Trade Item Number)

- Custom serialized numbers

- Internal asset IDs

If you’re working toward compliance mandates (like GS1 Sunrise 2027), using a standardized EPC format such as SGTIN ensures compatibility across trading partners.

Example structure of an SGTIN:

- Company Prefix

- Item Reference

- Serial Number

Planning your data structure ahead of time prevents duplicate IDs and ensures scalability.

Using RFID Encoding Software

Encoding typically happens through:

- RFID-enabled printers (print + encode in one step)

- Desktop RFID encoders

- Fixed or handheld RFID readers with write capability

Most businesses use encoding software that:

- Pulls data from ERP or WMS systems

- Generates serialized EPC values

- Sends encoding commands to the printer

- Verifies the tag was written successfully

For organizations using MarkMagic, RFID encoding can be built directly into the label design and print process. MarkMagic supports EPC generation, serialization, and RFID printer control, allowing users to print and encode RFID labels in a single step. Because it integrates with ERP, WMS, and host systems, businesses can automatically populate EPC data from live transactional data — eliminating manual entry and reducing errors.

This ensures every tag is uniquely serialized, accurately encoded, and validated before it leaves the printer.

Printing and Encoding

With an RFID printer, the process begins by loading the RFID label roll into the printer and connecting the device to your encoding software. Once connected, you send the appropriate data file or print job to the printer. The printer then writes the EPC data directly to the RFID chip embedded in the label while simultaneously printing the human-readable information and any required barcodes on the surface of the label.

After encoding, the system verifies that the EPC was written correctly and matches the intended value. If a tag fails during the encoding process, most RFID printers automatically mark the label as void and advance to the next one to maintain accuracy and production efficiency.

Verifying the Tags

Verification is critical. Without it, even a small encoding error can ripple through your supply chain and cause receiving delays, compliance failures, or inventory discrepancies. A tag that appears properly printed may still contain incorrect or unreadable EPC data, which is why post-encoding validation is essential.

After encoding:

- Scan the tag with an RFID reader.

- Confirm the EPC matches the expected value.

- Ensure readability from proper distances.

In production environments, automated RFID portals or tunnels verify encoded tags before shipment — eliminating downstream errors.

Best Practices for RFID Encoding

When encoding RFID tags, it’s important to use serialized, non-repeating EPC values to ensure every tag has a unique identity within your system. After encoding, consider locking the appropriate memory banks if security or data integrity is a concern, especially in regulated or high-value environments. Always test tag readability in real-world conditions to confirm consistent performance across expected read distances and environmental factors. Monitoring encoding failure rates can also help identify printer calibration issues or defective tag batches early.

Finally, integrating RFID encoding directly with your ERP or WMS streamlines operations, reduces manual errors, and ensures data accuracy across your entire workflow.

Common Encoding Mistakes to Avoid

Even small mistakes during the encoding process can create major downstream issues, from shipment rejections to inventory inaccuracies and compliance penalties. Because RFID systems rely on precise, unique data, errors at the encoding stage tend to multiply as products move through the supply chain.

- Writing duplicate EPC numbers

- Using incorrect memory banks

- Encoding tags not designed for your surface type

- Skipping verification steps

- Not aligning with retailer compliance standards

Final Thoughts

Encoding RFID tags isn’t just about writing numbers to a chip — it’s about building a reliable identification system that powers real-time visibility.

When done correctly, encoded RFID tags enable:

- 95% inventory accuracy

- Faster shipping validation

- Reduced shrink

- Automated compliance reporting

If you design your encoding workflow properly from the start, you’ll avoid costly rework and build a foundation for scalable RFID success.

Interested in RFID?

An RFID tracking system can help organizations of all sizes improve their supply chain efficiency. Contact the CYBRA team to schedule a demo today.