Pharmacode

What is a Pharmacode?

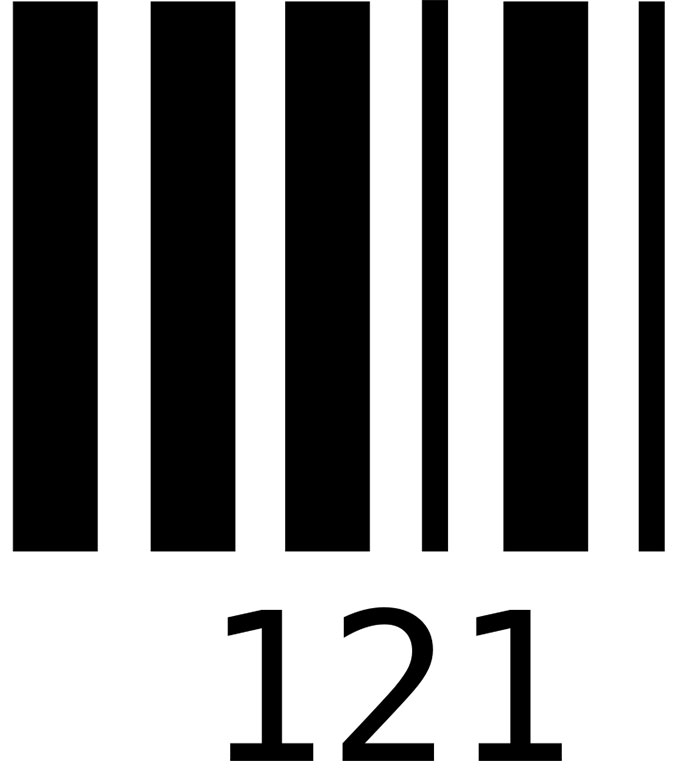

A Pharmacode is a barcode used in the pharmaceutical industry. These codes can be printed in a wide range of colors, and they can be read by lasers or other light-emulating devices. The bars have at least two and up to 16 bars.

In the pharmaceutical industry, tight regulatory controls mean that products must be labeled correctly. This means that they must have extensive packing control systems. Additionally, pharmaceutical products must meet stringent Drug Enforcement Administration rules, including chain of custody records. Using a pharmacode provides a robust system for maintaining such records, which is why it is becoming increasingly prominent.

Pharmacode

Use Cases

The primary use case for pharmacodes is in packaging verification, ensuring that the correct labels and packaging are applied to the right products, reducing medication errors. Pharmacode is also essential in automated production lines, where it facilitates high-speed scanning and error detection. Additionally, it is used in regulatory compliance, helping manufacturers meet stringent quality control standards.

- Packaging verification – Ensures correct labeling and prevents errors.

- Production line automation – Enables high-speed, reliable scanning.

- Error detection – Helps identify mislabeling before distribution.

- Regulatory compliance – Assists in meeting pharmaceutical safety standards.

- Serialization – Supports product tracking and counterfeit prevention.

Decoding Pharmacode

Pharmacode is decoded using specialized barcode scanners or vision systems designed to read its unique binary format. Unlike traditional barcodes, pharmacode represents data using bars of varying widths rather than spaces. The decoding process follows these steps:

- Scanning the Code – A camera or laser-based scanner captures the image of the pharmacode from the product packaging.

- Binary Conversion – The scanner converts the bar pattern into a binary sequence, where each bar width corresponds to a specific binary value.

- Decimal Interpretation – The binary sequence is then converted into a decimal number, which corresponds to a predefined value in the manufacturer’s database.

- Validation and Error Detection – The decoded value is checked against expected data to ensure correct labeling, preventing packaging errors.

Since pharmacode can be read in one direction only and supports limited numeric values, it is highly reliable for quick and accurate identification in high-speed pharmaceutical packaging environments.