CYBRA’s MarkMagic® Drives Over Air Labeling Solution for Pharmaceutical Cold Chain Logistics

The $18 billion cold chain pharmaceutical logistics market¹ is focused on ensuring regulatory compliance, supply chain visibility, product integrity and security, and shipping accuracy in the transport of temperature-sensitive medicines. CYBRA Corporation and a major healthcare services company leveraged software and sustainability to deliver an innovative cold chain solution.

The Challenge

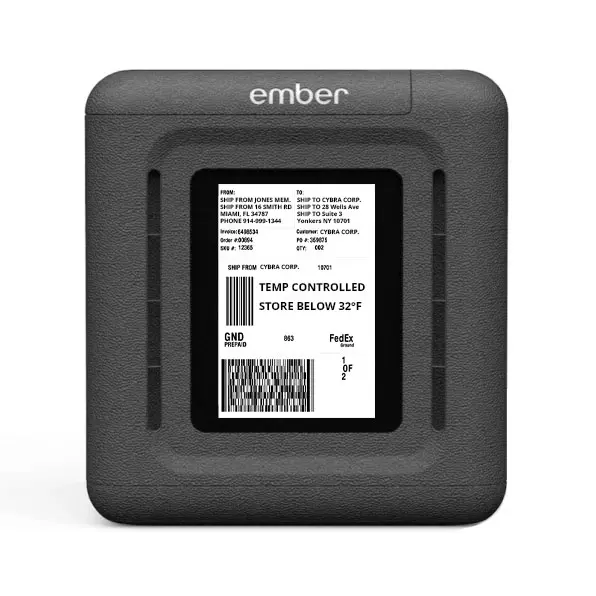

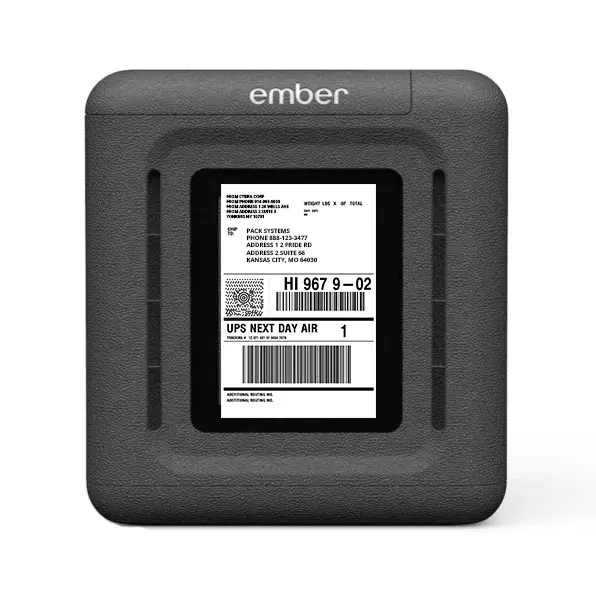

A global manufacturer and distributor of pharmaceuticals and medical and laboratory products needed to ensure the safe and timely transport of temperature sensitive material, while also reducing shipping waste. The pharmaceutical manufacturer partnered with Ember Technologies, Inc. to create specialized self-refrigerated shipping containers that are capable of cloud-based temperature reporting, GPS location tracking, and return-to-sender technology. These containers, known as Ember Cubes, checked the sustainability box for the pharmaceutical manufacturer as the shipping cubes are reusable. The Ember Cube boasts an onboard cellular radio to report real-time temperature and humidity, as well as GPS location information. Instead of the pharmaceutical manufacturer’s staff printing an industry standard bar code label, the Ember Cube incorporates an e-ink screen situated on one side of the shipping cube. Once an Ember Cube is packed and ready to go, a digital shipping label appears on the e-ink screen and the Ember Cube is shipped.

The missing ingredient was the creation of the shipping label images that appear on the e-ink screen, with the ability to change the destination as needed and produce return label images. The pharmaceutical manufacturer required an industry veteran labeling software application provider that could meet the requirements and provide dependable support.

The Solution

The pharmaceutical manufacturer turned to CYBRA Corporation, developers of world-class MarkMagic Bar Code Labels, RFID Tags, and Forms Software. CYBRA demonstrated how MarkMagic would empower the pharmaceutical manufacturer’s personnel to produce the e-ink image, change the destination as needed, and manage the safe return of the eco-friendly Ember Cube — all through the Cloud.

To fully leverage the capabilities of the Ember Cubes and to ensure the timely and accurate delivery of temperature-sensitive products, the pharmaceutical manufacturer opted for CYBRA’s MarkMagic software. MarkMagic’s reliability was evidenced by thousands of satisfied customers worldwide since 1990, including several of the most prominent global pharmaceutical companies. A final clincher in the decision process was that the pharmaceutical manufacturer uses Manhattan Associates’ WMS, warehouse management system, which has been fully integrated with MarkMagic for over 25 years.

MarkMagic, working in tandem with the Ember Cube, eliminates the need for a thermal printer, barcode label stock, and special bar code label ribbons. Want to re-route a cube that’s already in transit? With MarkMagic, labels can be changed at any point during the container’s journey. In fact, after the cube arrives at its destination and is emptied of its contents, the shipping service is notified that it is ready to be picked up, and a shipping return label is generated on the e-ink screen “over the air,” replacing the previous e-ink image with the new actionable shipping information. The MarkMagic label images have been vetted by selected shipping carriers — most recently, Federal Express — to confirm that all barcodes can be read throughout the distribution process.

The Benefits

The Ember Cube self-refrigerated package combined with MarkMagic’s barcode label solution provides labeling efficiency through the cloud to support the pharmaceutical manufacturer’s sustainability agenda, in addition to streamlining the deployment of their cold chain solution. It provides critical cold supply chain visibility and eliminates the cost, bother, care and feeding of expensive bar code printing equipment and supplies.

“MarkMagic simplified how we generate the labels needed to utilize Ember Cubes,” said the pharmaceutical manufacturer’s IT supply chain execution manager. “We wouldn’t have an Ember solution without MarkMagic.”

Finally, by not depending on often harried personnel consistently matching a physical label to the right box in a hectic distribution center, the solution ensures that the appropriate label automatically appears on the e-ink screen with no manual intervention.

So, when is a label not a label? When its image appears in digital form, eliminates waste and errors, and can be changed on the fly by its originator.