In the global textile industry, labeling compliance is crucial for manufacturers, retailers, and consumers alike. Textile labels serve as the primary communication tool between the producer and the consumer, conveying essential information about the fabric, care instructions, country of origin, and safety standards.

With varying regulations across different countries and regions, ensuring compliance in textile labeling can be a daunting task. However, with the right textile labeling software, manufacturers can streamline the process, reduce errors, and ensure that their labels meet all necessary regulations.

In this article, we will explore how to make compliant global textile labels using textile labeling software, focusing on the key elements of compliance, the benefits of using specialized software, and the steps to create effective and compliant labels.

Textile Labeling Regulations by Region

Textile labeling regulations vary by region, but they all aim to provide consumers with clear and accurate information about the textiles they purchase. Here’s an overview of the textile labeling requirements in the US, Canada, Mexico, and the EU:

United States

In the United States, textile labeling regulations are primarily governed by the Textile Fiber Products Identification Act (TFPIA) and enforced by the Federal Trade Commission (FTC). These regulations ensure that consumers receive accurate and clear information about textile products, which helps them make informed purchasing decisions. Here’s an overview of the key requirements:

Fiber Content

- Labeling: The label must disclose the fiber content of the textile product, including the percentage of each fiber type used. For example, a label might read “70% Cotton, 30% Polyester.”

- Order of Predominance: Fibers must be listed in descending order of their weight in the product. Any fiber making up less than 5% of the total weight can be listed as “Other Fibers” or omitted, although including it is often recommended for transparency.

Country of Origin

- Mandatory: The label must state the country where the product was manufactured. This requirement helps consumers understand where the product comes from and supports transparency in the supply chain.

Manufacturer or Dealer Identity

- Identification: Labels must include the name or identification number of the manufacturer, importer, or dealer. This provides a point of contact for consumers and helps authorities trace the product if issues arise.

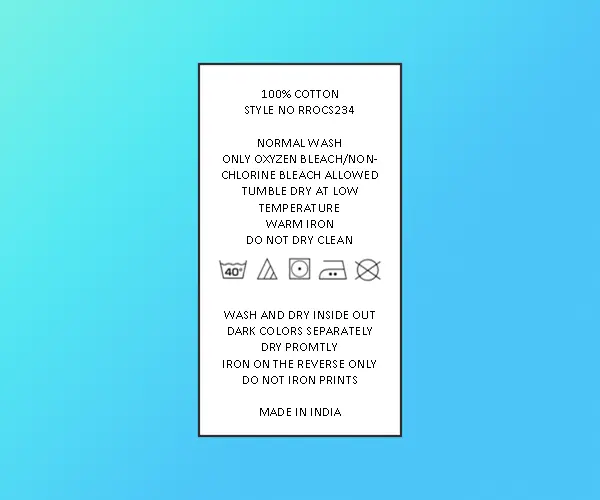

Care Instructions:

- Recommended but Not Mandatory: While not a strict requirement under the TFPIA, providing care instructions is encouraged. These instructions help consumers understand how to properly maintain the textile product to extend its lifespan.

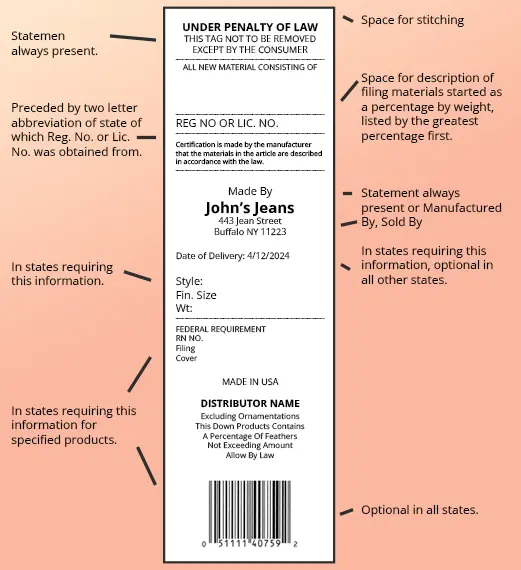

US Labeling Example:

Canada

Textile labeling regulations in Canada are primarily governed by the Textile Labelling Act and its associated Regulations. These rules ensure that textile products are accurately labeled, which helps consumers make informed purchasing decisions. Here’s a detailed overview:

Fiber Content

- Labels must disclose the fiber content of the textile product. This means the label should state the percentage of each fiber used in the product.

- The fiber content must be listed in descending order of predominance. For example, a label might read “70% Cotton, 30% Polyester.”

- If a fiber constitutes less than 5% of the total weight, it does not need to be listed, although including it is generally encouraged for transparency.

Country of Origin

- The label must indicate the country where the textile product was manufactured. This helps consumers understand where the product was made and supports transparency in the supply chain.

Dealer Information

- The label should include the name or the business name of the manufacturer, importer, or distributor. This provides a point of contact for consumers if there are issues or questions about the product.

Care Instructions

- While not mandatory, including care instructions on the label is strongly recommended. These instructions help consumers maintain the textile product properly and ensure its longevity.

Mexico

Textile labeling regulations in Mexico are primarily governed by the NOM-004-SCFI-2006 standard, which is issued by the Secretaría de Economía (Ministry of Economy). These regulations aim to ensure that textile products are labeled in a way that provides clear, accurate, and useful information to consumers. Here’s a comprehensive overview:

Fiber Content

- Labeling: The label must clearly state the fiber content of the textile product. This involves specifying the percentage of each fiber type used. For example, a garment labeled “80% algodón, 20% poliéster” indicates it is 80% cotton and 20% polyester.

- Order of Predominance: The fibers must be listed in descending order of their weight in the product.

Country of Origin

- Mandatory: The label must indicate the country where the product was manufactured. This is required to inform consumers about the origin of the product and to support transparency in trade.

Manufacturer or Importer Information

- Identification: The label must include the name, business name, or registered trademark of the manufacturer, importer, or distributor. This helps consumers and authorities trace the product back to its source.

Care Instructions

- Required: Labels must include care instructions, which guide consumers on how to properly wash, dry, and maintain the textile product. These instructions are usually provided through standardized care symbols.

Additional Requirements

- Product Specificity: Labels should be specific to the product type and include any additional information necessary for the consumer to understand and properly use the product.

EU

Textile labeling regulations in the European Union are primarily governed by Regulation (EU) No 1007/2011 on textile fiber names and related labeling and marking of the fiber composition of textile products. This regulation ensures transparency and consistency in textile labeling across EU member states. Here’s a detailed breakdown:

Fiber Content

- Labeling: Labels must clearly state the fiber content of the textile product. This means listing the percentages of each fiber type used. For example, “50% Cotton, 50% Polyester” indicates the proportions of each fiber.

- Order of Predominance: Fibers must be listed in descending order of their weight in the product. Any fiber constituting less than 5% of the product can be omitted from the label, though including it is encouraged for clarity.

Fiber Names

- Standard Terminology: The regulation provides standardized names for fibers to avoid confusion. For instance, terms like “cotton,” “wool,” and “polyester” are used consistently across all member states.

Country of Origin

- Not Mandatory: Unlike some other regions, the EU does not require the country of origin to be stated on the label, although it may be included voluntarily to provide additional information to consumers.

Care Instructions

- Mandatory Symbols: Labels must include standardized care symbols that inform consumers about the proper maintenance of the textile product. This includes instructions for washing, drying, ironing, and other care procedures.

- International Standard: The symbols used are based on the ISO 3758 standard, which ensures consistency in care instructions across different countries.

Additional Textile Labeling Compliance Elements

In addition to the core labeling elements such as fiber content, country of origin, manufacturer identity, and care instructions, textile labeling regulations in the US, Mexico, Canada, and the EU may include several other compliance elements. These additional requirements help ensure that products are safe, accurately represented, and meet various legal and consumer expectations. Here’s a breakdown of these additional elements for each region:

- Flammability Information: The Consumer Product Safety Commission (CPSC) regulates the flammability of children’s sleepwear and other garments. Labels must comply with flammability standards and often include warnings or safety information.

- Hazardous Material Certification Marks: For products that contain or are treated with certain chemicals, additional labeling may be required to inform consumers of potential hazards.

- Organic or Eco-Friendly Certifications: If a product claims to be organic or has environmental certifications, such as GOTS (Global Organic Textile Standard), it must adhere to the certification’s labeling requirements.

- Environmental or Ethical Certifications: Labels may need to include certifications from bodies like OEKO-TEX or other environmental and ethical standards if claimed.

- EU Ecolabel: If a product has an EU Ecolabel, it must include this certification on the label, demonstrating compliance with EU environmental standards.

- Recycling Information: Labels may need to include information about recycling or disposal of the textile product to meet environmental regulations.

- Genetically Modified Organisms: If a product makes claims about being GMO-free, it must adhere to specific EU regulations and labeling requirements related to genetically modified organisms.

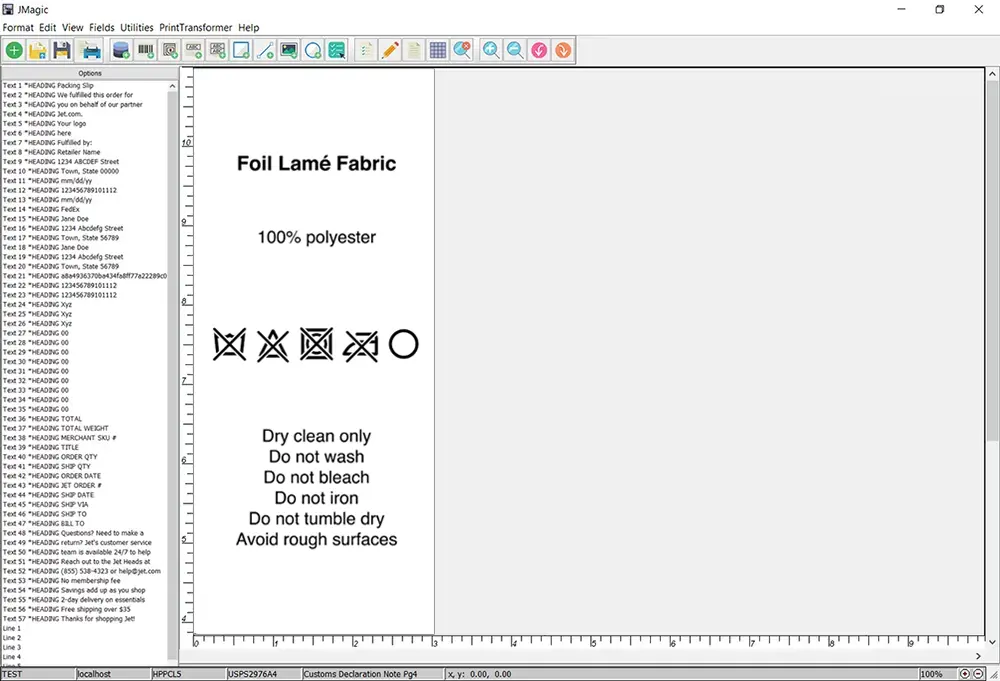

Given the complexity of these regulations, textile labeling software becomes an indispensable tool for ensuring that labels are compliant across multiple markets.

Benefits of Textile Labeling Software

Using specialized textile labeling software offers numerous advantages over manual or general-purpose labeling methods. These benefits include:

1. Regulatory Compliance

Textile labeling software is designed to help manufacturers comply with the various labeling requirements across different regions. The software typically includes pre-built templates and compliance checks that ensure all necessary information is included on the label. This reduces the risk of non-compliance, which can lead to fines, product recalls, or reputational damage.

2. Multi-Language Support

As global markets require labels to be in different languages, textile labeling software often includes multi-language support. This feature allows manufacturers to easily create labels in multiple languages, ensuring that they meet the linguistic requirements of each market.

3. Customizable Templates

With textile labeling software, manufacturers can use customizable templates that ensure consistency and accuracy across all labels. Templates can be tailored to specific products, regions, or customer requirements, making it easier to manage labeling across a diverse product line.

4. Automated Data Integration

Textile labeling software can integrate with other business systems, such as ERP (Enterprise Resource Planning) or PLM (Product Lifecycle Management) systems. This integration allows for the automatic importation of product data, reducing the risk of human error and ensuring that labels are always up-to-date with the latest information.

5. Scalability

For manufacturers with large-scale operations, textile labeling software offers scalability. The software can handle high volumes of labels, ensuring that production runs smoothly even during peak times.

6. Audit Trails and Reporting

Many textile labeling software solutions include features for tracking and auditing label creation. This ensures that manufacturers have a clear record of how labels were created, who approved them, and when they were printed. This can be crucial for compliance and quality control purposes.

7. Efficiency and Cost Savings

By automating the label creation process, textile labeling software reduces the time and resources required to produce compliant labels. This leads to greater efficiency, lower labor costs, and faster time-to-market for new products.

Conclusion

Creating compliant global textile labels is a complex task that requires careful attention to detail and a thorough understanding of regulatory requirements. By using textile labeling software, manufacturers can simplify this process, ensuring that their labels meet all necessary regulations while also improving efficiency and reducing costs. From multi-language support to automated compliance checks, textile labeling software offers a comprehensive solution for managing the complexities of global textile labeling. As the textile industry continues to evolve, staying ahead of regulatory changes and maintaining compliant labeling practices will be essential for success in the global market.

Better Labeling, Faster Printing.

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.