The Globally Harmonized System (GHS) for classifying and labeling chemicals ensures that hazardous materials are universally labeled and communicated for safe handling, shipping, and storage. GHS shipping labels play a crucial role in this system by providing critical safety information for anyone involved in the transportation or handling of dangerous chemicals.

What is GHS?

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) is an international standard developed by the United Nations to ensure consistent classification and labeling of chemicals across countries. Its purpose is to improve safety by standardizing the way chemical hazards are communicated through labels and Safety Data Sheets (SDS). GHS labels include pictograms, signal words, hazard statements, and precautionary information to help workers, shippers, and consumers handle chemicals safely. GHS is used in many industries, including shipping, manufacturing, and healthcare.

Key Elements to a GHS Shipping Label

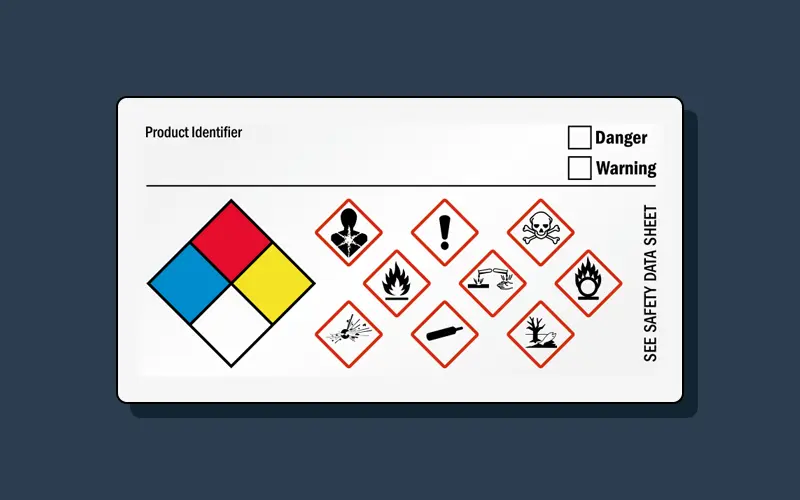

To comply with GHS regulations, shipping labels must include the following key elements:

1. Product Identifier

The product identifier should clearly state the chemical name or the unique identification number (such as a Chemical Abstract Service (CAS) number). This ensures that the chemical can be easily referenced and matched to its corresponding Safety Data Sheet (SDS). The product identifier must be prominently displayed on the label to avoid any confusion in identifying the substance.

2. Pictograms

GHS pictograms are standardized images used to represent specific hazards associated with the chemical. These symbols are enclosed in red diamond-shaped borders and are universally recognizable. There are nine pictograms that convey different types of hazards, including:

- Flame: For flammable materials.

- Skull and Crossbones: For acute toxicity.

- Corrosion: For substances that cause burns or damage to skin, eyes, or metals.

The relevant pictograms should be included based on the chemical’s hazards, ensuring that handlers can quickly assess the associated risks.

3. Signal Word

GHS labels must include a signal word that indicates the severity of the chemical’s hazard. There are two approved signal words:

- Danger: For chemicals with a severe hazard.

- Warning: For chemicals with less severe hazards.

Only one signal word should be used per label, based on the highest level of hazard present.

4. Hazard Statements

Hazard statements provide detailed information about the nature of the chemical’s risks. These statements are standardized by GHS to describe specific hazards, such as:

- “May cause cancer”

- “Highly flammable liquid and vapor”

- “Causes severe skin burns”

Each hazard statement is linked to a particular hazard class, and the label must list all relevant statements for the chemical being shipped.

5. Precautionary Statements

Precautionary statements are instructions on how to handle, store, and dispose of the chemical safely. There are four types of precautionary statements:

- Prevention: Measures to avoid or reduce exposure (e.g., “Keep away from heat”).

- Response: Emergency measures in case of exposure (e.g., “If on skin: Wash with plenty of water”).

- Storage: Guidelines for safe storage (e.g., “Store in a well-ventilated place”).

- Disposal: Proper disposal procedures (e.g., “Dispose of contents/container in accordance with local regulations”).

The correct precautionary statements must be included to ensure the safety of anyone handling the chemical.

6. Supplier Identification

The label must contain the contact details of the chemical’s manufacturer or supplier, including the company name, address, and phone number. This ensures that in the event of an emergency or inquiry, the appropriate party can be contacted for further information.

7. Supplemental Information

In some cases, additional information may be required by specific countries or industries. Supplemental information can include details about first-aid instructions, specific handling procedures, or emergency contact numbers.

Why GHS Labels are Important

GHS shipping labels play a crucial role in enhancing safety across global supply chains. By standardizing hazard communication, they help prevent accidents, ensure compliance with international regulations, and protect workers from chemical exposure. Clear labeling allows for the quick identification of chemical hazards, enabling workers, emergency responders, and others in the supply chain to handle chemicals appropriately and safely.

Moreover, proper GHS labeling is essential for meeting regulatory requirements. Non-compliance with GHS labeling can result in legal penalties, fines, and the rejection of shipments, which can disrupt business operations. Therefore, businesses involved in the transportation, distribution, or handling of hazardous chemicals must ensure their shipping labels are fully compliant with GHS guidelines.

How to Create and Print GHS Labels

Creating and printing GHS-compliant labels can be a complex process, especially for companies dealing with a wide range of chemicals and hazards. Fortunately, there are software solutions that simplify this process.

MarkMagic, a versatile barcode and labeling software, is an ideal tool for generating GHS-compliant shipping labels. MarkMagic allows businesses to design, print, and manage shipping labels that include all the necessary GHS elements—product identifiers, pictograms, hazard and precautionary statements, and more. Its intuitive interface and robust features make it easy to stay compliant with GHS regulations while ensuring that the labels are clear, accurate, and easy to read.

MarkMagic also supports integration with existing enterprise systems, such as ERP and WMS platforms, to automate label creation and streamline the shipping process. With support for various printers and formats, MarkMagic can help businesses of any size produce professional, GHS-compliant labels efficiently and cost-effectively.

By using MarkMagic, businesses can reduce the risk of non-compliance, improve operational efficiency, and ensure the safety of their workers and supply chain partners.

Better Labeling, Better Printing

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.