Labeling errors can have far-reaching consequences, from regulatory non-compliance to supply chain disruptions. According to a survey by AIIM, 60% of organizations identified labeling errors as a significant cause of delayed shipments and increased costs. That’s why label management is a vital part of any organization’s supply chain.

A robust label management system addresses these concerns, ensuring that labels are not just adhesive pieces of paper but strategic assets in the manufacturing and distribution landscape.

Manufacturers utilize Label Management Systems (LMS) to streamline and enhance various aspects of their labeling processes. These systems play a pivotal role in ensuring accurate, compliant, and efficient labeling, which is crucial for product identification, traceability, and regulatory adherence. Here’s how manufacturers commonly use Label Management Systems and their key applications:

- Product Identification

- Compliance with Industry Standards

- Efficient Change Management

- Integration with Manufacturing Processes

- Quality Control and Assurance

- Supply Chain Visibility

- Enhanced Efficiency and Error Reduction

- Adaptability to Varied Products

What is a Label Management System?

A Label Management System (LMS) is a software solution designed to streamline and automate the creation, printing, and management of labels and barcode labels across an organization’s operations. It provides a centralized platform where users can design label templates, manage label data, and control the printing process, ensuring consistency, accuracy, and compliance with regulatory standards.

An LMS allows businesses to create custom labels tailored to their specific needs, incorporating variable data such as product information, serial numbers, expiration dates, and barcodes. By eliminating manual processes and standardizing label creation and printing workflows, LMS helps improve efficiency, reduce errors, and ensure traceability throughout the supply chain, ultimately enhancing product identification, tracking, and safety.

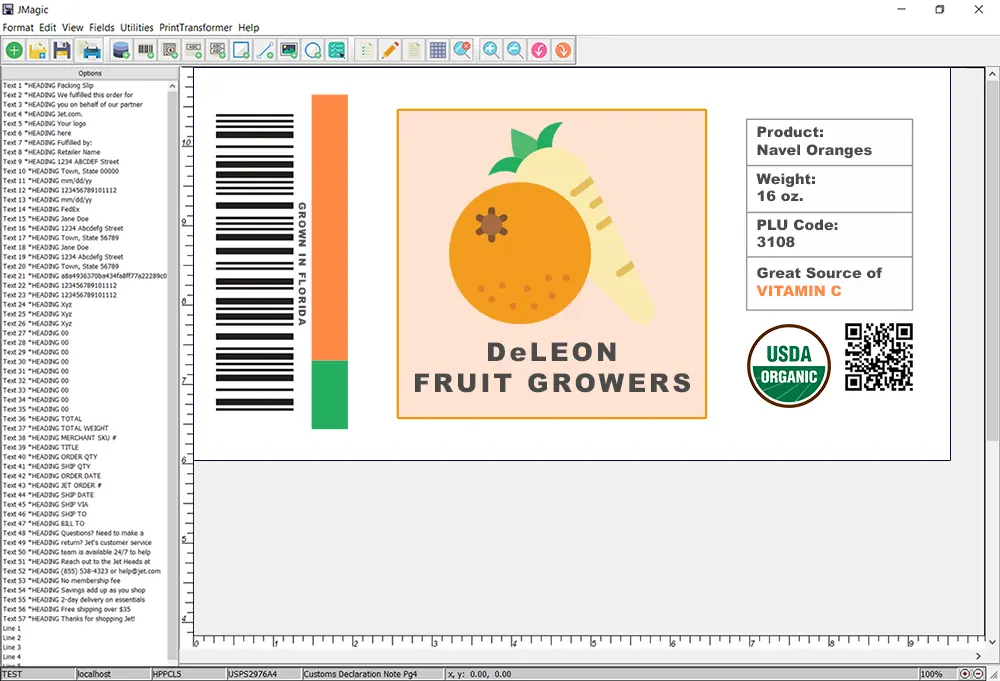

MarkMagic Barcode Label Printing Software from CYBRA

1. Label Design Software

Label design software is a critical component of a Label Management System (LMS), serving as the creative engine that allows users to design, customize, and manage labels efficiently. Your label design software should offer the following:

- User-Friendly Interface: An intuitive label design software empowers users with varied skill sets to craft visually appealing and informative labels effortlessly.

- Template Library: Statistics show that organizations with centralized label templates reduce design time by up to 40%, enhancing efficiency and maintaining consistency.

- Variable Data: Most modern label design software supports dynamic variable fields, allowing users to incorporate variable data such as serial numbers, batch numbers, and production dates. This is crucial for unique identification and traceability.

- Printing Compatibility: Label design software applications are compatible with various types of barcode label printers, ensuring that designed labels can be accurately and consistently printed.

2. Centralized Database

A centralized database offers a single, unified repository that stores and manages all relevant data and information needed for label creation and printing processes. This centralized database is a core component within a Label Management System (LMS), providing a structured and organized storage solution for various elements related to labels. Here’s an overview of what a centralized database in label printing offers:

- Product Information Management (PIM): According to a study by Ventana Research, 45% of organizations consider product information management a key priority. A centralized database ensures accurate and real-time data, reducing the risk of labeling errors.

- Open Data Access: With data stored in a centralized database, users can access the latest and most accurate information in real-time. This ensures that labels are generated with up-to-date data, contributing to accuracy and compliance.

- Data Integrity: Centralized databases often include validation checks to ensure the integrity and accuracy of the data entered into your labeling system. This helps prevent errors associated with incorrect or inconsistent information on labels.

3. Integration Capabilities: Breaking Down Silos

Many organizations, both large and small, rely on Enterprise Resource Planning (ERP) and Warehouse Management System (WMS) applications to keep their inventory accurate and supply chain efficient. Integrating label printing operations with an ERP or WMS brings about several benefits for organizations, enhancing efficiency, accuracy, and overall productivity in label creation and printing processes.

- ERP Integration Elegance: Modern barcode label printing applications offer APIs and other connectors that allow easy integration into other products and systems. Seamless integration with ERP and WMS systems translates into real-time data exchange. This not only reduces manual efforts but also mitigates the risk of data entry errors.

- Supply Chain Synchronization: A study by MHI reveals that 80% of companies believe real-time, end-to-end visibility into the supply chain is essential. Integration with supply chain systems ensures labels reflect the latest information, maintaining synchronization across the board.

4. Regulatory Compliance Tools: A Legal Safeguard

- Compliance Templates Triumph: The complexity of labeling regulations is evident in the fact that 65% of organizations struggle to keep up, as stated by Loftware. Compliance templates and tools become the compass guiding organizations through the intricate landscape of regulatory requirements.

- Audit Trail Assurance: A robust audit trail not only ensures traceability but also serves as a guardian of compliance. In an era where regulatory fines are a stark reality, a 360-degree view of labeling changes is more than a luxury; it’s a necessity.

How to Automate and Transform Your Forms and Label Processing

5. Workflow Automation: Orchestrating Effortless Processes

- Approval Workflows Ascendancy: Automated approval workflows prevent bottlenecks, ensuring labels undergo necessary reviews and approvals before gracing products. An AIIM study highlights that 40% of organizations see workflow automation as a key driver of efficiency.

- Event-Triggered Automation: Automation isn’t just a buzzword; it’s a lifesaver. Event-triggered label generation, tied to specific milestones, ensures labels are created precisely when needed, leaving no room for oversight.

6. Print Management

- Printer Integration Brilliance: The choice of printer matters, and integration with various types is a must. A study by Keypoint Intelligence indicates that 70% of organizations emphasize the importance of the right printer technology.

- Print Job Monitoring Mastery: In the dynamic world of manufacturing and distribution, tracking print jobs is pivotal. Real-time monitoring allows for quick response and reprinting if necessary, minimizing disruptions.

7. User Access Controls

- Role-Based Access Rigor: In a world where data breaches are a constant threat, role-based access controls safeguard sensitive label design and printing functions. Ensuring only authorized personnel have access reduces the risk of unauthorized changes.

8. Error Prevention and Verification

- Data Validation Vigilance: Accurate data entry is the linchpin of labeling success. Incorporating data validation checks minimizes the risk of errors, enhancing the reliability of labels.

- Barcode Verification Brilliance: According to a survey by Zebra Technologies, barcode scanning errors can occur in 12% of all scans. Barcode verification tools help ensure the accuracy of printed barcodes, reducing the risk of scanning errors in the supply chain.

The Future of Label Management Systems

As industries evolve, so do label management systems. The future promises even greater integration with emerging technologies, increased automation, and a heightened focus on sustainability. Adopting a comprehensive label management system is not just about meeting today’s challenges; it’s an investment in the adaptability and resilience required for tomorrow’s endeavors. In the dynamic tapestry of manufacturing and distribution, where precision meets pace, a label management system isn’t just a tool—it’s the orchestrator of success.

Better Labeling, Better Printing

Ensure every label is accurate, compliant, and printed without delays. Discover how CYBRA’s barcode and printing solutions streamline operations and eliminate errors.